Facility layout is a complex and sometimes maddening process. You are often limited by budget, space, time, or schedule beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one?

Facility layout is a complex and sometimes maddening process. You are often limited by budget, space, time, or schedule beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one?

Tags: facility layout, EHS

Posted in Space Optimization & Planning|

It’s easy to say that you’re striving for 100% accurate pick rates, but how realistic is that goal? And should it be the actual number you shoot for? Mis-picked orders, any number of them, are expensive. Incorrect orders are expensive to re-pick. They’re expensive to return and restock. Shipping dollars are lost both directions. Most importantly, mistakes are expensive because they can cost you customers.

Tags: ROI

Posted in Order Picking & Fulfillment|

Carousels are a high performance order picking technology option, but only if you match them to the right operational needs and applications. If you are considering a carousel system for your operation, it’s important to understand when these “goods to person” picking systems are appropriate, and where manual picking might still work better for you. The real issue is, can you make a carousel, or any automated solution, outperform a good manual system?

The answer is: not always. Let’s look at ways you can push your project in the right direction.

Tags: industrial carousels, storage density

Posted in Automation, Labor & Efficiency|

When approaching pallet rack choices, cost, storage density and construction elements all play a role in making a choice. While cost is always a prime concern, be mindful that cost is often tied to storage density. Cheaper pallet rack tends to not have as much storage density as more expensive rack. But before you consider cost, you must decide what applications you will use the pallet rack for.

Tags: gravity flow rack, selective pallet rack, structural, seismic, mobilized

Posted in Pallet & Warehouse Racks|

Forklifts are ubiquitous in warehousing and other industrial operations, but aren’t necessary in many other applications, such as small assembly shops, retailers, auto dealerships, and others that require materials movement but do not need a forklift, with its maintenance costs, safety issues, driver requirements and its footprint in a smaller facility. What methods can you use instead?

Tags: lift transporters, powered lift hand truck, portable stacker, counterweight, non-forklift, Material Handling, stackers

Posted in Safety & Ergonomics|

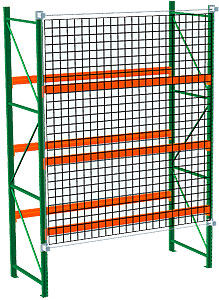

People store all kinds of things on pallet rack – from truck engines to fine jewelry. How do you protect valuable goods from being accessed by unauthorized personnel? What about inventory toppling off the back of the rack into an aisle where workers are?

Tags: Pallet Rack, warehouse safety, Pallet Rack Safety Netting, Rack Security Cages

Posted in Pallet & Warehouse Racks|

All too often, companies struggle because the size of their warehouse is considered in the planning stage, but not the efficient use of that space.

A facility is purchased or leased with the desired set of characteristics, and then work begins. There are significant opportunities in many operations to size up the business mix, order trends, product slotting and facility layout in a way that helps improve everything from storage density to pick rates to error rates to labor costs. But first we must know the total storage potential of the facility, and work backwards from there.

Tags: storage space, facility layout, warehouse storage

Posted in Space Optimization & Planning|

Facility layout is a complex and sometimes frustrating process. You’re often limited by budget, space, time, or scheduling beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one? Facilities are sometimes designed without consideration for the space EHS compliance may consume. When that happens, your usable footprint shrinks, leading to a production facility that isn’t truly space-optimized.

Posted in Safety & Ergonomics|

When I was a kid, on rainy days my friends and I used kitchen chairs, old blankets and lots of clothespins and built our own special space for imaginary adventures. Our rag-tag shelter was temporary, but gave us the sensation of being in our own little world. Frequently, in manufacturing and warehousing facilities, work zones and independent departments need separation from the larger whole for either safety or autonomy purposes, and there are products out there that answer those needs. Products like curtain walls, acoustic walls, thermal barriers and welding screens. Read the rest of this entry »

Tags: curtain walls, acoustic, barrier, thermal, strip door, plastic, vinyl, welding, screen, warehouse space savings

Posted in Safety & Ergonomics|

Above: a driver security cage, which allows entry into a dock area door, but restricts access within the facility

It’s difficult enough to handle the people who are supposed to be in your plant every day, much less visitors. Even those you invite.

The problem has two components: safety and security. From a safety standpoint, you have no idea how an untrained guest might behave. That guest may not know which machines are dangerous. He may not know to use your specified pedestrian walkways, wear steel toe boots, or stay clear of running conveyors. He doesn’t have your safety training. From a security standpoint, guests can be problematic from a number of angles. A plant visitor who has access to storage areas has access to inventory. With even the cheapest of phones now having good cameras and video built in, a guest may photograph something you don’t want made public. That guest could also damage something, accidentally or otherwise. There are lots of wrinkles.

Tags: Industrial Security, plant safety, Safety & Ergonomics

Posted in Security|