Pallet racks are probably the most common warehouse storage equipment in the world, and for good reason: they’re safe, versatile and use the vertical cube of high-bay warehouses when correctly specified, loaded, unloaded and used within the rack’s tolerance. Load distribution–the way a load sits on your racks–is a critical factor for safe usage. Here’s how to get it right.

Pallet Rack Load Distribution Guide

Tags: warehouse storage, pallet racks, rack safety, RMI

Posted in Pallet & Warehouse Racks|

Key Ways to Maximize Space in Your 3PL

In a recent report of current industrial and logistics trends released by the CBRE, the prevailing theme among U.S. Tenants and Landlords is that of shrinking available space. While this should come as no surprise to those within the logistics community, the rate at which warehouse vacancy is dwindling is far outpacing the increase in new construction (new supply trails leasing demand by 1.5 to 1). This puts 3PLs in a predicament, but also provides opportunities for those who can maximize their available footprint.

Tags: warehouse space savings, Warehouse Management, 3p, logistics, Racks, warehouse storage, storage, mezzanine, warehouse, storage space, Third Party Logistics

Posted in Space Optimization & Planning|

Laying the Groundwork for Using a 3PL Service

Companies are utilizing 3PL services for their warehousing and shipping needs more often than ever. Many of the companies who choose to shift their operations to third parties are e-commerce entities that specialize in producing and selling a product and don’t want to run a storage and shipping facility. Others are traditional distributors, retailers, and others who believe that they should focus on core competencies.

If your company is considering a 3PL for its warehousing, shipping and logistics needs, what information do you need to have ready?

Tags: ecommerce, 3PL, logistics, warehouse storage, warehouse, ROI, Third Party Logistics

Posted in Warehousing & Distribution|

How to Measure and Improve Industrial Storage Space Efficiency

All too often, companies struggle because the size of their warehouse is considered in the planning stage, but not the efficient use of that space.

A facility is purchased or leased with the desired set of characteristics, and then work begins. There are significant opportunities in many operations to size up the business mix, order trends, product slotting and facility layout in a way that helps improve everything from storage density to pick rates to error rates to labor costs. But first we must know the total storage potential of the facility, and work backwards from there.

Tags: storage space, facility layout, warehouse storage

Posted in Space Optimization & Planning|

Innovations in High Density Storage

Ever find yourself wondering how you can get more out of your pallet rack? Do you have goods that take up very little space, but your pick operations don’t call for entire pallets full of the product? Then you might need to look at ways to achieve more density in your storage, and we’ve recently found a gem of a product that can help you out. It’s called Dynamic High Density Storage and it’s made by SpeedCell.

Tags: Warehouse Management, warehousing, Pallet Rack, order fulfillment, warehouse storage, space savings, storage, industrial storage, distribution center, Order Picking & Fulfillment

Posted in Pallet & Warehouse Racks|

Avoid Common Warehouse Layout Mistakes

It’s not easy to understand when facility layout is causing significant problems for an operation.

The way the warehouse is planned and laid out can affect everything in a warehouse or distribution facility. You may be suffering from over-forecasted demand for product and under-forecasted need for square footage. Executives may not fully understand what it takes to receive, store and ship orders. What are some of the more common problems when it comes to facility layout?

Tags: 3PL, warehouse storage, Third Party Logistics, facility layout, ecommerce

Posted in Space Optimization & Planning|

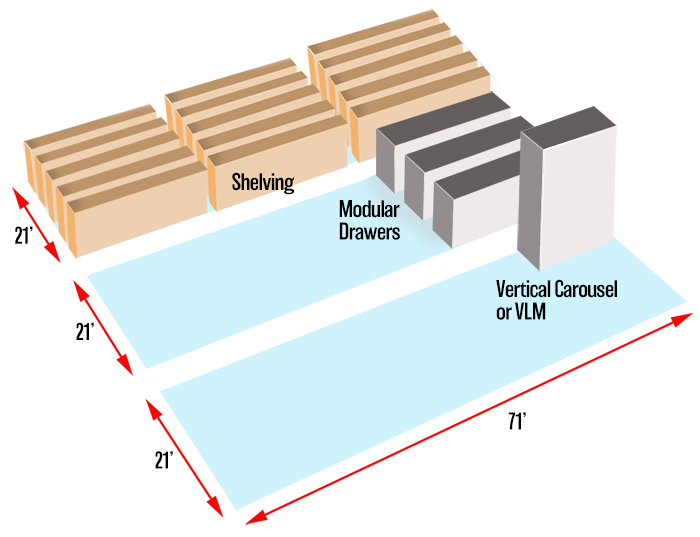

Storage Efficiency: Shelves vs. Modular Drawers vs. Flow vs. Vertical Carousels

Storage systems are designed for different goals, but space efficiency is always important for growing and evolving warehouses and manufacturing facilities. Which storage equipment suits you, your application, product and needs?

Above: a visual comparison of space utilization featuring various methods. The vertical carousel provides the same amount of storage space as several rows of shelving or modular drawer storage. In this instance, the carousel saves over 1,400 square feet of floor space compared to shelving. Flow racks also compare favorably to shelving in terms of space utilization.

Tags: warehouse storage, space savings

Posted in Space Optimization & Planning|

Wire Security Cages: Welded vs. Woven

With the focus on plant security the last few years, it’s little wonder that companies are outfitting their warehouses with security partitions and cages for high-value inventory, restricted access areas, tool cribs, and other places where more physical control of the property is needed. They are superb in these functions, keeping tools, components and inventories safe for a relatively low cost vs. other kinds of security measures.

Tags: inventory control, security, warehouse storage, theft prevention

Posted in Security|