What Does a Warehouse Management System Do?

A medium-sized chain of convenience stores once asked me to take a look at their Warehouse Management System (WMS) to see if it was time for an upgrade. After documenting all the functions it performed, we discovered that none of them could be described as serving warehouse activities. The system had lots of good purchasing functions—but offered nothing to support the actual warehouse.

Read the rest of this entry »

Tags: WMS, Factory Automation, Warehouse Management

Posted in Automation, Labor & Efficiency|

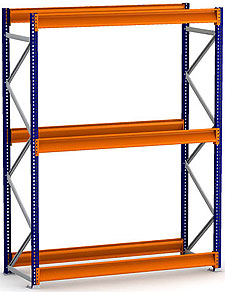

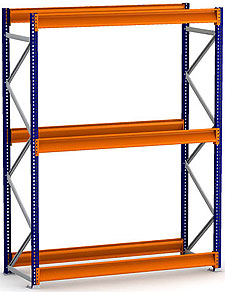

There are all kinds of shelving options for typical loads, but what do you do with the really heavy, dense, or bulky items that just won’t work on conventional shelving, but that aren’t loaded on a pallet rack? Or things that aren’t big enough to store on pallet racks, but don’t fit into standard shelving? That’s where wide span bulk shelving comes into play. It’s similar to pallet rack, but built for hand-loaded case or piece storage.

Read the rest of this entry »

Tags: Wide Span Shelving, high capacity, bulky items, large items, wide items

Posted in Storage, Organization & Workstations|

More and more companies are adding various forms of robotics to their operations as they seek to improve productivity, enhance worker safety, and keep labor costs down. We recently spoke with Wes Garrett, Packaging Account Manager at FANUC America about robotics in the material handling industry. He provided some great information regarding cost of ownership, indicators robotics may benefit an operation, and trends in new technologies.

Read the rest of this entry »

Tags: palletizing, Robotics, Packaging

Posted in Automation, Labor & Efficiency|

These collisions have done some damage

In both cases, the guard rail has deformed. That’s good (kind of), because both guardrails have done their jobs and protected the people, equipment or facility structures behind them. On the other hand, you can see that the rail systems have been damaged. Let’s see how they match up in form, function and lifetime cost. Typically when you have a forklift barrier, it will eventually be impacted, and those impacts can be direct or indirect, fast or slow, serious or cosmetic. When the impact is direct, fast and damaging, what are the critical differences in rigid and flexible rail systems?

Read the rest of this entry »

Tags: Steel guard rail, Flexible polymer guard rail, traffic control, pedestrian, inventory, structure, forklift safety, guarding systems

Posted in Safety & Ergonomics|

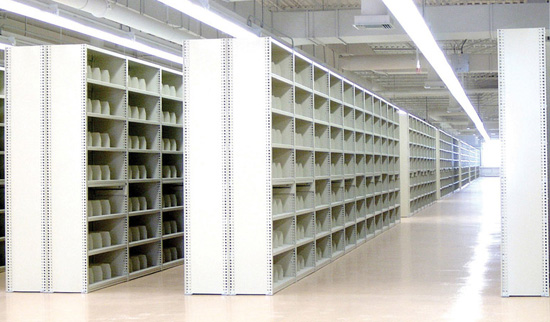

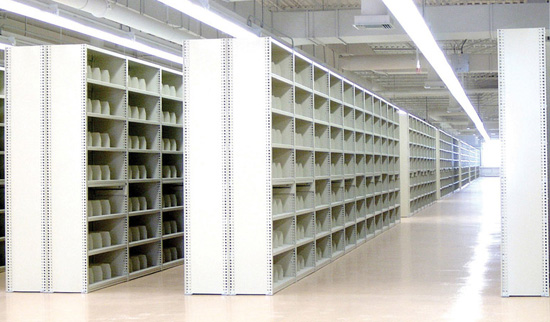

When most of us look at steel shelving we see, well, steel shelving, but the truth is, you can customize it more than any other type of industrial shelving to give you additional storage options that better fit your specific storage needs.

Let’s examine some of the possibilities.

Read the rest of this entry »

Tags: closed shelving, drawer modules, bin shelving, parts storage, compartmentalized, Rousseau, Hallowell, Western Pacific, steel shelving, open shelving

Posted in Storage, Organization & Workstations|

Forklifts are often acknowledged as the top safety issue in warehouse and distribution center operations. A number of things make this true: first, forklifts account for 1% of industrial accidents, but 10% of injuries. Secondly, a given forklift has a 90% chance of an accident during its useful life. More alarming is that forklifts account for 85 to 100 deaths in the United States ever year. Let’s explore some ways you can make forklift use safer in your facility.

Read the rest of this entry »

Tags: guard rail, operations, accessories, traffic sensor, cab cover, tine guide, blue light, training, forklift safety, forklift

Posted in Forklift - Pedestrian Safety|

We published an article in the third quarter of the MHEDA Journal, Automation and Labor: Can’t They Get Along? The point of that article is that for American labor, robots aren’t currently reducing employment so much as changing it. Automated industries tend to be more profitable and less vulnerable to offshoring and other job-reducing factors.

Our friends at AutoQuip brought up another point—that automated systems and lifts can add valuable years to the working lives of high-skill, aging employees.

Read the rest of this entry »

Tags: labor

Posted in Automation, Labor & Efficiency|

Guardrails are used to separate people, structures, machinery and valuable assets from heavy forklifts weighing more than 10,000 pounds. The requirements for durability and impact resistance are demanding, yet many don’t understand what types of impacts their systems can endure, and under what circumstances. The issue is compounded by the fact that many manufacturers simply don’t provide impact ratings for their guard rails. Some companies fabricate and install home-made railing, which is likely to never have been rated at all.

What can you do to ensure your guard railing system can protect your employees and property the way it’s supposed to?

Read the rest of this entry »

Tags: traffic management, guard rail systems, facility safety, hand rails, bollards

Posted in Safety & Ergonomics|

Rivet shelving is one of the most versatile forms of industrial shelving available. With individual shelf capacities up to 1,400 pounds, it rivals the load capacity of heavy wide span or pallet rack but is designed for carton and case storage. It assembles quickly due to its tear-drop and pin connectors and is extremely sturdy whether using a single-rivet or double-rivet design. It’s also available in an amazing array of sizes and layouts.

Read the rest of this entry »

Tags: storage, rivet shelving, Penco, Western Pacific Storage Solutions, carton

Posted in Storage, Organization & Workstations|

In warehousing and storage operations where inventory is stored high on racks, it’s a sad fact of life: sometimes pallets or cartons fall.

They fall because they’re stacked wrong. They fall because an order picker or a forklift bumps them. They might fall because the pallet breaks or was poorly stacked. They fall due to seismic activity, rack failure or just plain mistakes. There are plenty of reasons they fall, but how can you reduce your risks?

Read the rest of this entry »

Tags: warehousing, Safety & Ergonomics, Racks

Posted in Pallet & Warehouse Racks|

Read our customer reviews