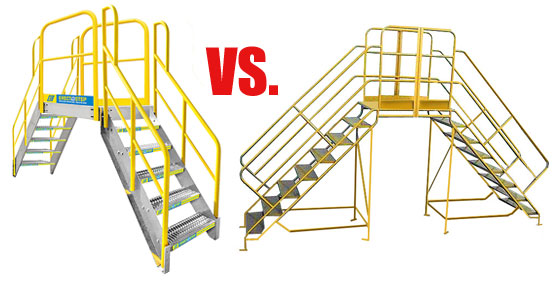

In many operations, things like conveyors or pipe runs or other machinery interrupt the flow of a work floor, and the obvious way to get around it is to erect a crossover. This is commonly done in larger scale conveyor systems with longer lines, but we also do them for other areas where going around the obstacle could take significant time, or where access is limited by other factors. The question is, what type of crossover best fits your needs?