We have all seen the spectacular (sometimes humorous), but often horrifying videos of rack collapses. They’re all over YouTube. But what really happens to cause these dangerous incidents?

We have all seen the spectacular (sometimes humorous), but often horrifying videos of rack collapses. They’re all over YouTube. But what really happens to cause these dangerous incidents?

Tags: warehouse racking, industrial safety

Posted in Pallet & Warehouse Racks|

Check out this video from ESH Safety News America for some common ways people fall in a variety of situations. The video is informative, and sometimes funny (see the shovel part), but the consequences of a slip & fall accident certainly are no laughing matter.

Tags: industrial accident prevention, plant safety

Posted in Safety & Ergonomics|

There isn’t much value in a worker walking across a facility; value is realized at work areas, not in transit between them. In many operations, order pickers can walk as many as 12 miles a day. This level of walking makes workers tired and more prone to error, injuries, and declines in productivity. While some degree of walking is unavoidable, much of this is simply commuting time to retrieve supplies, or inefficient design that makes the job harder and less efficient than it should be.

How can you reduce time walking, and increase the time people spend getting things done?

Posted in Space Optimization & Planning|

There is some confusion about the different finishes that can be applied to a pallet rack wire deck.

Various manufacturers offer different finishes, and you may have need of more than one of them for different types of storage applications. This primer on the common finish options can help you make decisions about your warehouse, load, rack and application.

Tags: pallet storage, wire decking, pallet racking, ROI

Posted in Pallet & Warehouse Racks|

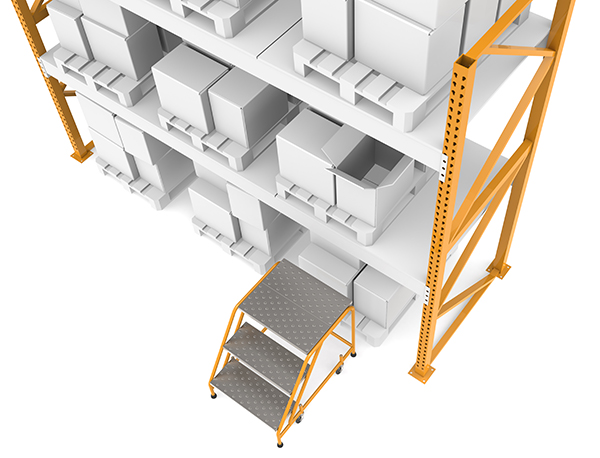

To save time, people sometimes climb pallet racks to pick orders or do other things. This should never happen. While it’s faster to climb than it is to bring a rolling stair ladder or a forklift in to do it right, it’s dangerous and counterproductive. Do it long enough and there will be injuries.

Tags: warehouse rack, plant safety, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

There is nothing inexpensive about a new facility.

The cost of real estate (or lease costs), new equipment, people, regulatory compliance, and potential downtime add up very quickly, even for a relatively small operation. But reconfiguring your current operation has its own challenges. You have to deal with operating in a construction/renovation environment, the potential that the redesign won’t serve your needs through future growth, new equipment, and more. It’s a difficult choice.

Tags: 5S principles, facility design

Posted in Space Optimization & Planning|

The warehouse. The office.

Sometimes it’s as if one doesn’t exist to the other. As one of our customers told us, “it’s like we have two companies here, and one doesn’t know what the other is up to.”

But when you’re trying to operate better, it’s impossible to separate the two functions. Decisions can be made in one area that can impact the other severely, so communication and cooperation are vital. Too bad it doesn’t always work that way. How can you improve it?

Tags: labor, ROI, Warehouse Management, warehousing

Posted in Warehousing & Distribution|

Whether you’re operating a dedicated distribution center or the order fulfillment or stock warehouse of a manufacturing operation, most industrial facilities deal with storage and warehousing to some degree. In the not-so-distant past, warehousing was treated mostly as a cost center – a necessary evil that had to exist so that the more profitable parts of an enterprise could operate. Thankfully, more enlightened thought has prevailed recently.

Order fulfillment and storage are not just places you can save money – they can earn money. If the gremlins don’t get you.

Tags: Automation, labor, operations

Posted in Warehousing & Distribution|

In a recent blog post, Auburn professor Dr. Kevin Gue, one of the bright minds in the industry when it comes to the business of industrial distribution and plant operations, reflected on the reaction to his ProMat 2013 talk on “Designing a Worker-Centric Facility”. Gue has smart points about the relationship between safety and ROI – and how you can deal with those issues.

Tags: industrial safety, ergonomics, ROI

Posted in Safety & Ergonomics|

Pallet rack is typically safe and easily-maintained storage equipment, whether you are dealing with selective, pushback, drive-in, or other types of rack. But if you load it wrong, if you don’t inspect and repair/replace damaged components, if you don’t understand your capacities, and if you don’t take steps to ensure your rack isn’t impacted by loading equipment, that safe rack can become dangerous and expensive.

We have created an infographic to help you navigate the most common mistakes people make dealing with pallet racks. Feel free to share this graphic to any site or other media. It is the first of many infographic posters we’ll be offering to help people operate and maintain material handling equipment.

Posted in Pallet & Warehouse Racks|