Structural vs. roll-form racks: which fits your application and operation best?

Roll-form selective rack is the standard for many industrial storage operations. It’s the go-to rack due to its teardrop assembly, ease of use, and strength. Because it doesn’t require bolts or other hardware (aside from a snap-on safety clip) to attach beams to uprights, it’s a popular option for selective industrial pallet storage operations. But there is another option: structural rack with bolt-on beam/frame connections, higher capacities and rigidity.

Why would you use structural racks rather than roll-form racking?

Read the rest of this entry »

Tags: Heavy Rack Systems, Impact Resistance, racking, industrial storage, Steel King

Posted in Pallet & Warehouse Racks|

When you have bulk materials to store and handle, when is it best to stack them on the floor, and when do you need to move it to storage equipment like heavier racks? How can you safely and effectively stack these materials on the ground? OSHA offers some guidelines on the question from a safety perspective. When you do opt for either floor stacking or rack storage, what are some safeguards you should take?

Read the rest of this entry »

Posted in Material Handling|

What specialized applications do you have for shelving? Cold storage capable? Biohazard resistant? Air flow through shelves? Fire sprinklers able to reach all levels? Bin storage and easy visibility of shelf contents? All these are great reasons to go with wire shelving, which can serve multiple purposes in a facility and is less likely to retain airborne dust and debris.

Let’s look at some of the wire shelving options available.

Read the rest of this entry »

Tags: wire shelving, chrome, zinc, epoxy, finish, stainless steel, sprinkler, ventilation

Posted in Storage, Organization & Workstations|

In manufacturing & distribution, safety is an area of top concern, for both the protection of workers and financial ramifications for companies. We spent some time at ProMat with Kelly Kamlager from Ladder Industries to examine the importance of safety and compliance for industrial companies.

Read the rest of this entry »

Tags: warehousing, OSHA, Safety & Ergonomics, hiring

Posted in Safety & Ergonomics|

The long path from person to product

In a distribution or warehousing operation, the most common working concept is “person-to-goods” order picking, which simply means that order pickers move to storage locations, often pushing or pulling carts and reading orders off the paper. These pickers spend significant amounts of time walking between storage, and are then expected to decipher an order picking sheet. These operations spend lots of money and time and resources on those steps. Picking paths and storage locations evolve as inventory profiles change — and not always for the better.

Read the rest of this entry »

Posted in Order Picking & Fulfillment|

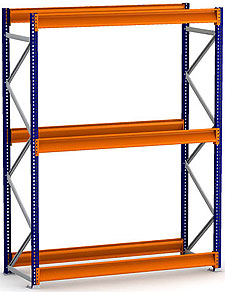

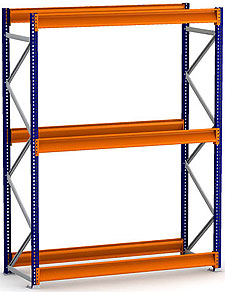

There are all kinds of shelving options for typical loads, but what do you do with the really heavy, dense, or bulky items that just won’t work on conventional shelving, but that aren’t loaded on a pallet rack? Or things that aren’t big enough to store on pallet racks, but don’t fit into standard shelving? That’s where wide span bulk shelving comes into play. It’s similar to pallet rack, but built for hand-loaded case or piece storage.

Read the rest of this entry »

Tags: Wide Span Shelving, high capacity, bulky items, large items, wide items

Posted in Storage, Organization & Workstations|

More and more companies are adding various forms of robotics to their operations as they seek to improve productivity, enhance worker safety, and keep labor costs down. We recently spoke with Wes Garrett, Packaging Account Manager at FANUC America about robotics in the material handling industry. He provided some great information regarding cost of ownership, indicators robotics may benefit an operation, and trends in new technologies.

Read the rest of this entry »

Tags: palletizing, Robotics, Packaging

Posted in Automation, Labor & Efficiency|

These collisions have done some damage

In both cases, the guard rail has deformed. That’s good (kind of), because both guardrails have done their jobs and protected the people, equipment or facility structures behind them. On the other hand, you can see that the rail systems have been damaged. Let’s see how they match up in form, function and lifetime cost. Typically when you have a forklift barrier, it will eventually be impacted, and those impacts can be direct or indirect, fast or slow, serious or cosmetic. When the impact is direct, fast and damaging, what are the critical differences in rigid and flexible rail systems?

Read the rest of this entry »

Tags: traffic control, pedestrian, inventory, structure, forklift safety, guarding systems, Steel guard rail, Flexible polymer guard rail

Posted in Safety & Ergonomics|

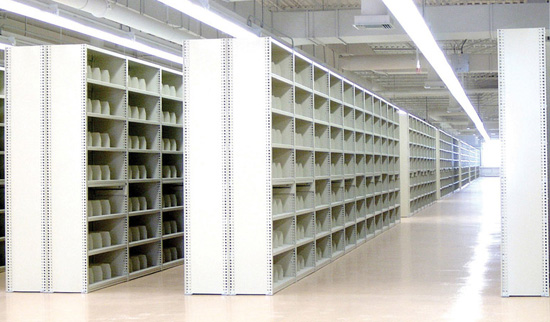

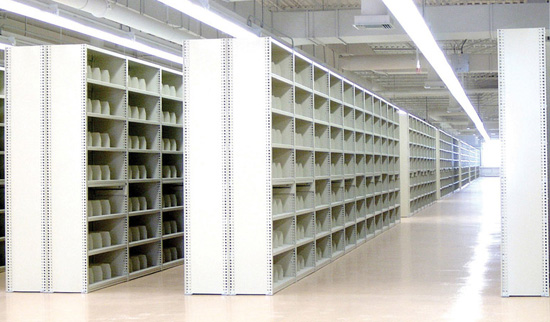

When most of us look at steel shelving we see, well, steel shelving, but the truth is, you can customize it more than any other type of industrial shelving to give you additional storage options that better fit your specific storage needs.

Let’s examine some of the possibilities.

Read the rest of this entry »

Tags: bin shelving, parts storage, compartmentalized, Rousseau, Hallowell, Western Pacific, steel shelving, open shelving, closed shelving, drawer modules

Posted in Storage, Organization & Workstations|

Read our customer reviews

Read the rest of this entry »

Read the rest of this entry »