In warehouse & manufacturing operations, things get broken. They break in a number of ways, and it’s expensive. You’ve probably seen product broken or damaged in amazing and improbable ways if you’ve been in this business for any length of time. We had a client once buy a bunch of mismatched, used industrial shelving (not from us), only to see it collapse and dump thousands of tiny aircraft components on the floor. It had to be swept up and discarded since it was all mixed up and visually impossible to sort.

Those are extraordinary examples, but everyday inventory damage that cost “only” a few hundred or thousand dollars can savage your bottom line.

Read the rest of this entry »

Tags: warehousing, customer service, product damage, inventory control, damaged goods

Posted in Warehousing & Distribution|

Over the past four decades, we’ve seen plenty of operations move. We’ve installed entirely new conveyor systems into functioning operations without disturbing the flow of existing work. We’ve seen companies pick up an entire distribution operation and move it across two hundred feet of parking lot into another building. It’s not new territory for us, and if you have managed a manufacturing or warehousing operation long, it’s probably not for you either.

Read the rest of this entry »

Posted in Warehousing & Distribution|

We see two kinds of operations that have utilized AisleCop® forklift safety gate systems. The first are those companies who have defined traffic plans and are looking to prevent possible accidents in high-risk, limited-visibility, or heavy-traffic aisles. They foresee potential accidents and are taking measures to prevent them. The second kind are companies who have had an incident, or a near-miss.

Read the rest of this entry »

Tags: warehousing, warehouse safety, ROI, forklift safety, AisleCop

Posted in Forklift - Pedestrian Safety|

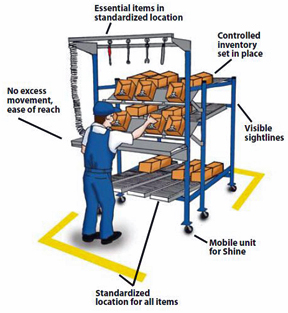

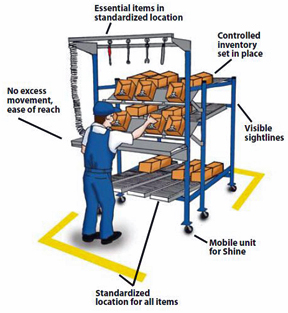

Based on 5 Japanese words that begin with “S,” the 5S Philosophy homes in on effective work place organization and standardized work procedures. When correctly implemented, it reduces waste and increases efficiency and overall work quality. You’ll also have a safer, more effective operation and employees who are more checked in than they were before. It simplifies work flow and helps you find inefficiency.

You may see things like empty flow racks, needless processes, over stocking, redundant operations, looming maintenance problems and more.

Read the rest of this entry »

Tags: 5S principles, lean manufacturing, lean warehousing, workstations, ergonomics, 5S workstations, quality

Posted in Storage, Organization & Workstations|

One easy way to gauge a warehouse or manufacturing plant’s effectiveness is to check how clean it is. Cleaner facilities are more productive, tend to be safer and tend to be more organized.

Whether your facility features gleaming floors or just keeps debris from packaging materials, pallets and accumulated junk under control, being cleaner is well worth the time investment. People who work in a disorganized facility where things just feel sloppy won’t work as well. They may make more errors. They won’t have pride in the operation. An inch of dust on rack beams or beneath conveyor legs sends a message to workers. You don’t need a sparkling facility with floors so clean you could have lunch on them, but a well-lit, organized, pleasant place to work can be helpful in employee attitudes and retention.

Read the rest of this entry »

Tags: warehousing, warehouse cleanliness, organization

Posted in Warehousing & Distribution|

The end of a manufacturing or distribution line is where the rubber meets the road for many operations. It’s potentially the last place where you have direct control of your product before it ships to retailers or direct customers. It’s where you can add a lot of value…or spoil a lot of value. The end of the line in many ways is more important to your company’s image as all its public relations, its websites, its brochures. It is often where your reputation can be made.

Read the rest of this entry »

Tags: Automation, palletizing, Robotics, Packaging, Conveyor

Posted in Automation, Labor & Efficiency|

If you are in the warehousing or material handling industry, you’ll find yourself identifying warehouse and handling equipment in movies or television shows quite often. Many of us have seen, for instance, the NFL graphics of a large distribution system used on Fox network for years. I’ve pointed out Hytrol conveyors in movies to my wife for years, to the point where she says it first when she sees it.

For fun, we have put together a list of the more famous scenes in entertainment history involving material handling equipment, and how it could have been done better.

Read the rest of this entry »

Tags: Material Handling, movies

Posted in Warehousing & Distribution|

In the last two decades, smart companies have identified the warehouse operation as a profit center, not a cost center. This is far from universal, but it inches toward that every day. No longer are warehouse managers considered box-hustlers – at least not in smart companies. Many are utilizing varying levels of automation. WMS is standard for larger operations and is making its way even to single-building, midsize and smaller ones.

Read the rest of this entry »

Tags: Automation, ROI, Robotics

Posted in Warehousing & Distribution|

Any operation with dock doors faces an uphill challenge when it comes to preserving the climate inside. In particular, air-conditioned and heated facilities must face the reality of losing large volumes of treated air when trailers must be loaded or unloaded. Managers will be asked to scrutinize every expense, and the loss of climate controlled air can be a significant expense.

So how can you minimize air and energy loss?

Posted in Docks & Shipping|

Retail distribution facilities have multiple options for shipping product to store locations. They can send full pallets which must be unwrapped, unloaded, and stocked at the store location. They can send packed carts that can easily be rolled onto store floors and stocked at the point of sale. What method works best?

Read the rest of this entry »

Tags: Safety & Ergonomics, warehousing, order fulfillment, Retail distribution

Posted in Order Picking & Fulfillment|

Read our customer reviews