Above: Rack supported mezzanine in a warehouse facility. Photo courtesy of Unex.

The typical U.S. distribution center is 31.1 feet tall, according to a survey by Statista. But when more space is needed for operations, mezzanines can be used to create it. Most facilities aren’t fully using that vertical cube, either. Rather than expanding out, you can expand up. Vertical storage options have options within as well (whoa, that got deep).

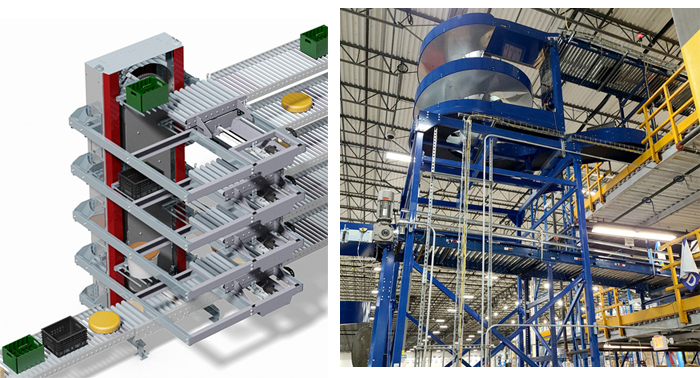

Tall racks are frequently deployed to utilize all if that vertical cube. If you have pallet rack, using part of it in the form of a rack supported mezzanine gains more from your vertical cube is an ideal solution. What could a rack mezzanine do for your facility?

Read the rest of this entry »