Vertical reciprocating conveyors—or VRCs—make it easy to move materials between levels, such as onto a mezzanine or down to basement storage. As you might expect, this equipment involves enclosures and access features for optimum safety. In this installment of our Shoptalk series, employee-owner Christine Perry offers a quick look at these features.

Shoptalk: Vertical Conveyor Safety Gates and Enclosures

Tags: Shoptalk

Posted in Lifting & Lift Systems|

Pallet Rack Safety: Preventable Risks

Pallet racks are safe and stable storage for pallets and bulk loads in warehouses, factories and other facilities, but you should be aware of the kind of dangers they pose when misapplied, modified or neglected. In any safety program, you’re always looking for risks you can prevent. What are some avoidable risks when it comes to pallet rack?

Tags: Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

Where to Add Warehouse Guardrails

Facility safety for many warehouses focuses on industrial traffic and vehicles like forklifts or stackers, and no wonder—the damage that a simple mistake can do, and the people that can be harmed—is considerable. There are many varieties of guardrail systems, and they all function a little differently but have the same role: solid protection for a critical area when all else fails.

Posted in Safety & Ergonomics|

Download Our Forklift Accessories Guide

The right accessories make your forklifts safer, more efficient and more productive. Because forklifts are a staple of most every warehouse, finding ways to make them more versatile and safer will always pay off. We believe that every forklift and warehouse can work better, and have released this new forklift accessories guide that shares some of our experience on the subject.

Posted in Material Handling|

Pallet Racks, Sprinkler Systems and Warehouse Fire Precautions

All warehouses have fire risks, ranging in severity. Facilities flammable loads like paper, aerosols, liquors or fiber are at higher risk than others, but any load on wood or plastic pallets can catch fire. For instance, manufacturing facilities with airborne debris are at more risk than those storing ceramics or steel components. While storage racks are not among leading causes of warehouse fires, (or even a cause, except for their loads) they can play an important part in reducing spread and damage.

Tags: Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

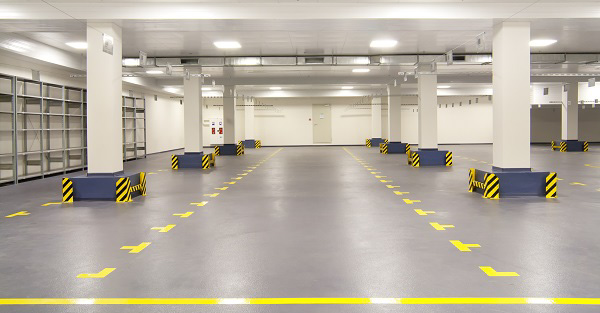

Why Floor Marking Is Essential

As we navigate this new age of Covid-19 and the distancing associated with it on all fronts of our lives, keeping areas within your facility safe and spaced becomes not only a priority now, but leads to further efficiency for operations in the future. Operations that utilize efficient means for creating visual clues within their warehouse showcase a more productive work environment that also keeps employees and equipment free from potential hazards.

One method to aid in this endeavor is floor marking. By marking areas in your facility, you highlight risks, outline areas for equipment and people, direct traffic and showcase safety considerations. In short, just by adding some color to your floor, you make your entire facility easier to navigate.

Posted in Space Optimization & Planning|

Tips for Better Drive-In Rack Specifications, Operations and Safety

When you need exceptionally high-density pallet storage, drive-in racks deliver space savings by eliminating forklift access lanes. They’re last-in, first-out storage ideal for stock that doesn’t need active inventory rotation and will be picked and used in a relatively fast manner. There are challenges to any storage system, of course. This guide should help you find ways to reduce the problems and operate your drive-in rack system more efficiently and safely.

Posted in Pallet & Warehouse Racks|

Download Our Guide To Safe, Efficient Loading Dock Operations

Loading docks are critical because they’re where everything is received—and eventually shipped. The right shipping & receiving setup means smooth product flow, faster putaway and more accurate fulfillment. In short, it means a safer and better operation. To help you protect your docks and your people, check out our new dock equipment guide.

Posted in Docks & Shipping|

How to Use Dockboards & Dockplates Safely and Effectively

Dock boards and dock plates are built to transition forklifts, pallet jacks, carts, people and other transportation methods between trailers and your warehouse dock area or staging floor. How can you be sure the transition between truck trailers and your dock is safe?

Tags: ergonomics, Safety & Ergonomics

Posted in Docks & Shipping|

Making Your Cantilever Rack Safe

Cantilever racks are built to handle long, heavy loads such as pipe or steel tube, lumber, wood or metal sheets, furniture, elongated crates and lots more. The design is simple–a central column with cantilevered arms extending from one or both sides. Safety is critical in any warehousing or industrial storage area, including cantilever storage. Given the heavy and bulky nature of the loads, here are some things you should be aware of to make sure your racks are safe.

Tags: Safety & Ergonomics

Posted in Pallet & Warehouse Racks|