Facility layout is a complex and sometimes maddening process. You are often limited by budget, space, time, or schedule beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one?

Facility layout is a complex and sometimes maddening process. You are often limited by budget, space, time, or schedule beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one?

Tags: facility layout, EHS

Posted in Space Optimization & Planning|

Carousels are a high performance order picking technology option, but only if you match them to the right operational needs and applications. If you are considering a carousel system for your operation, it’s important to understand when these “goods to person” picking systems are appropriate, and where manual picking might still work better for you. The real issue is, can you make a carousel, or any automated solution, outperform a good manual system?

The answer is: not always. Let’s look at ways you can push your project in the right direction.

Tags: industrial carousels, storage density

Posted in Automation, Labor & Efficiency|

Fork lifts are the mules of the industry, and we expect them to just power up and run when we need them to, but there are some very important safety aspects that should be taken care of before every shift. Safety steps that lengthen the service life of the vehicle, assure the vehicle operates as it should, and helps make it more visible to others working in the same space with the forklift. Read the rest of this entry »

Tags: Safety & Ergonomics, forklift, inspection, check levels, fork truck

Posted in Safety & Ergonomics|

These systems are at their best for open case picking systems. When you’re picking full pallets and cases, they’re less useful, although that depends on the situation. You can mix these systems in a single facility of pick pod area for maximum effect with inventory slotted to match the necessary profile. Each has a role, depending on what you’re picking, how your facility is set up, and the nature of your picking methodology. What might be best for a given situation?

Tags: pick to light, voice directed picking, RF systems

Posted in Automation, Labor & Efficiency|

Forklifts are ubiquitous in warehousing and other industrial operations, but aren’t necessary in many other applications, such as small assembly shops, retailers, auto dealerships, and others that require materials movement but do not need a forklift, with its maintenance costs, safety issues, driver requirements and its footprint in a smaller facility. What methods can you use instead?

Tags: stackers, lift transporters, powered lift hand truck, portable stacker, counterweight, non-forklift, Material Handling

Posted in Safety & Ergonomics|

We all know what happens to tooling and die when it’s stored haphazardly. Bumped and scratched, a chip here, a nick there, and suddenly your machining just isn’t what it used to be. The quality has slipped, maybe more products are being returned, there’s an increase in customer complaints. It’s too valuable and too expensive to risk. What are your options?

Tags: sheet metal storage, tool & die rack, tooling, machining, CNC, lathe, cutter

Posted in Pallet & Warehouse Racks|

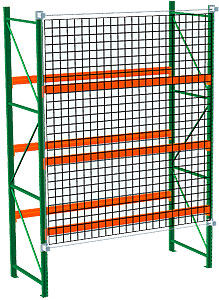

People store all kinds of things on pallet rack – from truck engines to fine jewelry. How do you protect valuable goods from being accessed by unauthorized personnel? What about inventory toppling off the back of the rack into an aisle where workers are?

Tags: Pallet Rack Safety Netting, Rack Security Cages, Pallet Rack, warehouse safety

Posted in Pallet & Warehouse Racks|

All too often, companies struggle because the size of their warehouse is considered in the planning stage, but not the efficient use of that space.

A facility is purchased or leased with the desired set of characteristics, and then work begins. There are significant opportunities in many operations to size up the business mix, order trends, product slotting and facility layout in a way that helps improve everything from storage density to pick rates to error rates to labor costs. But first we must know the total storage potential of the facility, and work backwards from there.

Tags: warehouse storage, storage space, facility layout

Posted in Space Optimization & Planning|

Choosing guard rail can be confusing unless you understand clearly what kinds of conditions you are protecting against and what assets you are protecting. Whether it be fall protection for workers or asset protection from industrial vehicle usage, there is a guard rail that fits that need.

Tags: warehouse safety, Safety & Ergonomics, guard rail, hand rail, guarding systems

Posted in Safety & Ergonomics|

Safety is a major issue in most industrial environments – especially those where industrial traffic like forklifts, AGV’s and other vehicles mingle with workers on foot. There are just too many ways people can get hurt; too many chances for things to suddenly go wrong. That’s why including some automated safety sensor systems in a facility can make a life and death difference on a day-to-day basis.

Tags: infrared sensor, industrial safety, forklift safety, traffic management, safety systems, safety sensors, motion detection

Posted in Forklift - Pedestrian Safety|