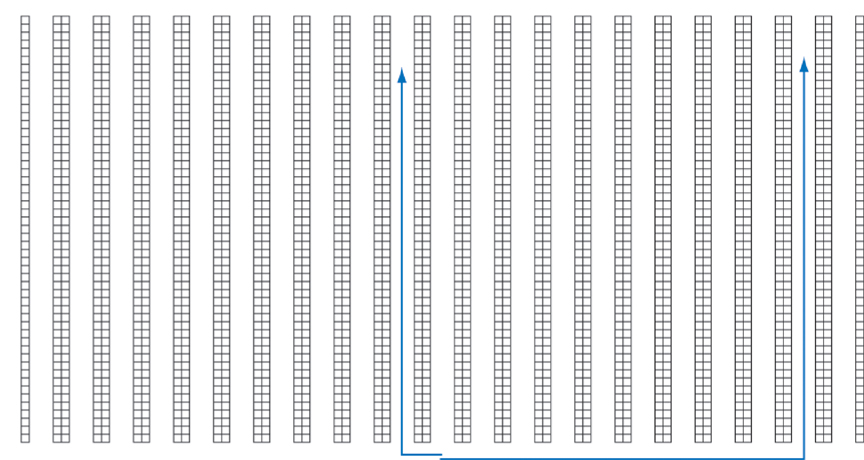

Facility layout is a complex and sometimes frustrating process. You’re often limited by budget, space, time, or scheduling beyond your control. What factors should you consider when you allocate space, either in a new facility or a redesigned one? Facilities are sometimes designed without consideration for the space EHS compliance may consume. When that happens, your usable footprint shrinks, leading to a production facility that isn’t truly space-optimized.