Heavy inventory stored high on racks have a chance for pallets or cartons to fall. How can you prevent this problem?

Heavy inventory stored high on racks have a chance for pallets or cartons to fall. How can you prevent this problem?

Tags: warehousing, Racks, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

Above: the edge of this pick module, which leads to a fall of over 20 feet, is guarded by a series of pallet flow swing gates.

When companies install storage platforms, the hustle and bustle of a busy working day can soften safety processes–a kind of soft that might lead to a hard and very expensive landing. Here are some ways you can reduce issue with work platform falls.

Tags: pedestrian safety, pedestrian gate, Space Optimization, Safety & Ergonomics, guard rail, handrail, mezzanine gate

Posted in Mezzanines & Industrial Platforms|

Fork lifts are the mules of the industry, and we expect them to just power up and run when we need them to, but there are some very important safety aspects that should be taken care of before every shift. Safety steps that lengthen the service life of the vehicle, assure the vehicle operates as it should, and helps make it more visible to others working in the same space with the forklift. Read the rest of this entry »

Tags: Safety & Ergonomics, forklift, inspection, check levels, fork truck

Posted in Safety & Ergonomics|

In the last 200 years 70% of jobs done by American workers have been replaced by automation – and during the next century we will see another automation revolution that replaces 70% of American jobs–again.

Tags: Automation, ergonomics, Safety & Ergonomics, Robotics, workers force

Posted in Automation, Labor & Efficiency|

If you’ve got conduit, tubing, rebar, pipe or bar stock, you need cantilever rack – period. Get it off the floor, off of standard shelving and pallet rack, and put it somewhere you don’t have to fight with it each time you need some. If you’re really smart, you’ll put it where overhead lift equipment can get to it – because once you get it stored right, you’ll wonder what the heck you were thinking earlier.

Tags: cantilever rack, crank out shelving, ergonomic, heavy duty cantilever rack, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

Choosing guard rail can be confusing unless you understand clearly what kinds of conditions you are protecting against and what assets you are protecting. Whether it be fall protection for workers or asset protection from industrial vehicle usage, there is a guard rail that fits that need.

Tags: warehouse safety, Safety & Ergonomics, guard rail, hand rail, guarding systems

Posted in Safety & Ergonomics|

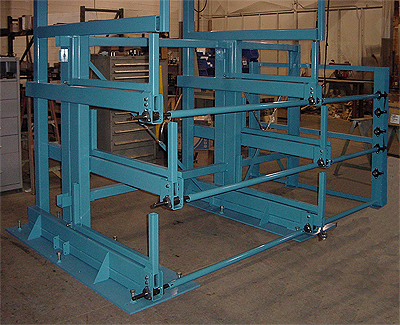

Above: a driver security cage, which allows entry into a dock area door, but restricts access within the facility

It’s difficult enough to handle the people who are supposed to be in your plant every day, much less visitors. Even those you invite.

The problem has two components: safety and security. From a safety standpoint, you have no idea how an untrained guest might behave. That guest may not know which machines are dangerous. He may not know to use your specified pedestrian walkways, wear steel toe boots, or stay clear of running conveyors. He doesn’t have your safety training. From a security standpoint, guests can be problematic from a number of angles. A plant visitor who has access to storage areas has access to inventory. With even the cheapest of phones now having good cameras and video built in, a guest may photograph something you don’t want made public. That guest could also damage something, accidentally or otherwise. There are lots of wrinkles.

Tags: Industrial Security, plant safety, Safety & Ergonomics

Posted in Security|

Conveyor safety should always be a top concern. With more than 50 workplace fatalities a year where conveyors are the primary source of injury and workplace accidents accounting for nearly 25% of all workers’ compensation claims, you must pay attention to industry standard safety practices.

Tags: Safety & Ergonomics

Posted in Conveyor Optimization|

Is this an unevenly distributed load? Concentrated load?

Line load? Point load? Load of something really heavy?

We have stressed this before: rack loads aren’t just simple weight vs. structure. The dimensions, shape, and size/density of the load as it sits on storage racks is absolutely critical to safe, effective warehouse storage. Our friends at Nashville Wire recently released an excellent piece that helps define the load types and how you can avoid incorrect or unsafe rack loading.

Tags: Pallet Rack, industrial storage, Safety & Ergonomics, storage rack

Posted in Pallet & Warehouse Racks|

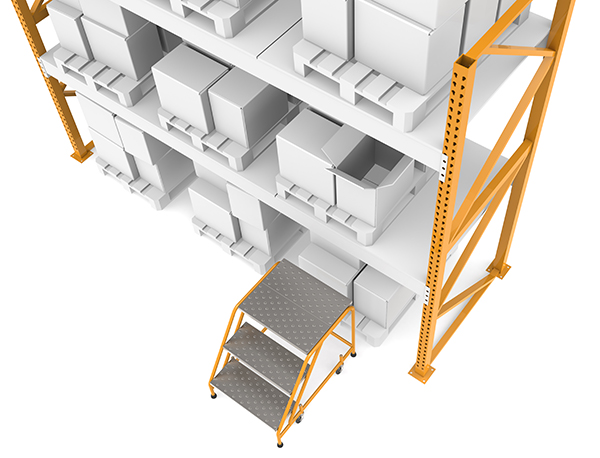

To save time, people sometimes climb pallet racks to pick orders or do other things. This should never happen. While it’s faster to climb than it is to bring a rolling stair ladder or a forklift in to do it right, it’s dangerous and counterproductive. Do it long enough and there will be injuries.

Tags: plant safety, Safety & Ergonomics, warehouse rack

Posted in Pallet & Warehouse Racks|