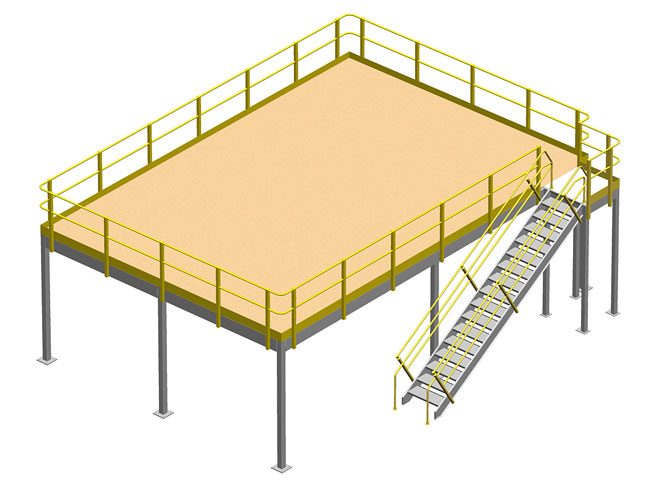

What a difference a name can make.

People tend to call any elevated platform a “mezzanine” in this industry, but that may be a mistake. When you are installing or otherwise specifying a platform, you need to be aware that the word “mezzanine” can cost you money and cause headaches when applied incorrectly.