write an introduction for this article

Tags: Automation, shipping, labor

Posted in Industry Insights|

Ensuring workplace safety is an ongoing challenge, especially in fast-paced manufacturing, warehousing, and material handling operations. Every year, the Occupational Safety and Health Administration (OSHA) publishes its list of the most frequently cited workplace safety violations, a snapshot of the most pressing hazards that can lead to injuries and serious fines.

While the list results don’t have many changes from year to year, it’s important to review annually. Comparing your safety processes and training to what’s included can help to create a more robust system that can save lives and protect what matters.

Posted in Safety & Ergonomics|

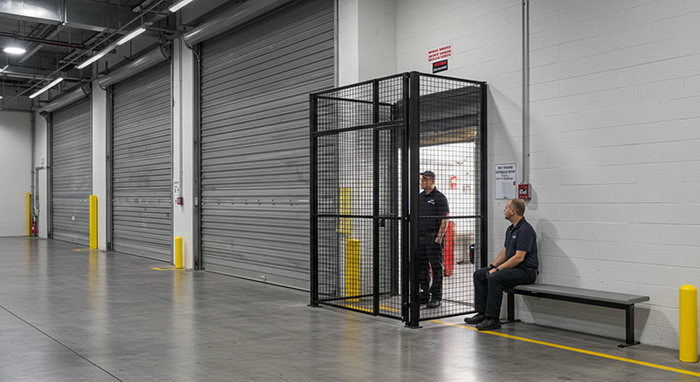

Truck drivers often need to enter warehouses when they deliver or pick up shipments. When they do, many warehouses have installed secure driver cages that let the driver into the facility, but not into the building at large. This can seem “driver-unfriendly” because they contain the driver. However, there are good reasons to install them while ensuring drivers have a good experience at your facility.

Tags: warehousing, dock security

Posted in Docks & Shipping|

Most pallet rack systems are installed with a starter-adder design, which shares a common rack upright between consecutive storage bays. The alternative is a double-post rack system, where each bay has two independent uprights. Most of the time, starter-adder is used because it’s more economical and uses space more efficiently.

Given that it’s costlier and uses more space, why–and where–would you use a double-post design?

Posted in Pallet & Warehouse Racks|

Above: Kevin Harwell and Bryan Gauger

On December 31, 2024, Kevin Harwell retired from Cisco-Eagle after an incredible 33 years of dedicated service. Kevin joined the company in February 1991 and has been an integral part of our success ever since.

Posted in ESOP & Company News|

This month, we’re looking at the growth of workers 65 or older, who choose to stay on the job. They now make up 22% of all American workers. How does that affect manufacturing and distribution operations? What can you do to accommodate these workers? Also: more on packaging automation, manufacturing in Texas and more.

Tags: warehousing, Manufacturing, labor

Posted in Industry Insights|

Cartons affect the full sequence of warehousing operations, but are frequently overlooked.

Besides carton sizes, you must also consider carton construction. One box out of square may not matter much; over a whole shipment, un-squared cartons can cause issues up and down the line. They don’t stack well, may not convey correctly and could result in product damage. In fact, you may pay higher shipping costs due to the size, composition and condition of the simplest thing: the carton.

Posted in Warehousing & Distribution|

This edition of our employee spotlight focuses on Erika Martin, Payroll & Benefits Specialist in our Dallas office. Discover Erika’s journey from marketing to HR, her dedication to helping others, and the impact of Cisco-Eagle’s employee-owned culture on her work.

Posted in ESOP & Company News|

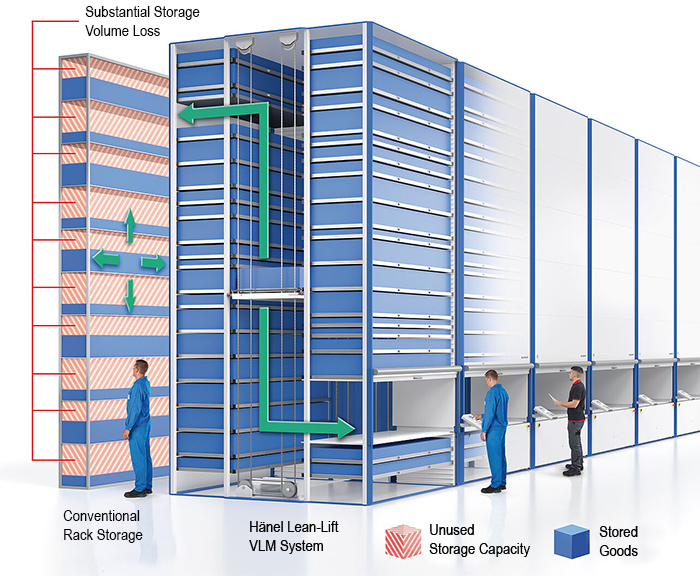

Above: VLMs condense space more efficiently than conventional storage racks, or even mini load systems. They can use the space more effectively because less “air space” is needed for the storage capacity.

Companies install carousel systems and vertical lift modules for many reasons, including flexibility, storage decentralization, operator access, retrieval times, security consolidation and picking accuracy gains. One of the most important reasons is the way they optimize space.

Posted in Space Optimization & Planning|

Every facility has its heroes—the shiny conveyor systems, towering pallet racks and state-of-the-art automation that seem to draw all the safety focus. But just like in any good action movie, even the heroes have a few weaknesses. Warehouses and manufacturing facilities are no different! These “weak links” are the areas that, if overlooked, can cause big safety issues. You can create a stronger, more resilient facility by paying attention to these sneaky trouble spots.

Posted in Safety & Ergonomics|