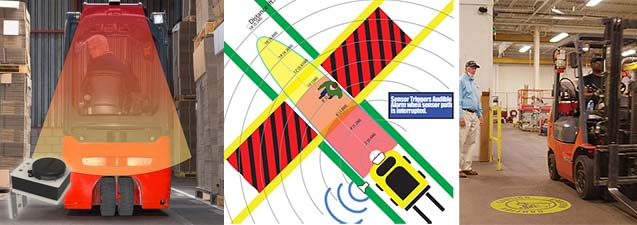

Like many technologies, forklift safety sensors and alarms progress the more the need is stressed. Cisco-Eagle’s Safety Automation Group has built a suite of solutions that can help in more specific situations. Let’s review some of the newest technologies you can implement and where they might be the most helpful.

A Review of New Forklift Safety Technologies & Methods

Posted in Forklift - Pedestrian Safety|

Forklift Multi-Tasking – Using Accessories That Matter

As new technologies emerge to help keep forklifts safer around pedestrians and each other, finding new ways to utilize your fleet of forklifts is more important than ever. Since supply chains are tight, more efficiency and safety should matter more than ever. Forklift accessories provide that aid in daily processes can offer that extra help without new lift trucks.

But what kind of accessories are out there?

Posted in Warehousing & Distribution|

Specifying High-Performance Parcel Handling Conveyor Solutions

The pressure on companies of all types to continuously ship faster and more efficiently has grown, particularly in the age of increased e-commerce, an extremely tight labor market and Covid-19 restrictions. Increased demand also affects retail distribution as companies work to develop effective delivery channels outside traditional ship-to-store.

The core mission of these operations is parcel shipping–an old art with new twists.

Tags: Automation

Posted in Conveyor Optimization|

Conveyor Transfer Options & Applications

When you need to transfer loads 90 degrees to conveyor lines, machinery or workstations, you have options—both standard and custom. Which transfer works best for your product, application and environment?

Posted in Conveyor Optimization|

Prevent Defense – Pallet Rack Protection Options from All Angles

Traffic coming and going within your facility’s pallet rack storage areas is a daily occurrence (or at least it better be!) and the higher the traffic, the better off your operations are probably doing. With tight supply chains, inventory shortages, longer lead times and limited patience from customers, movement around your rack is a constant. You can’t afford an accident. With that constant activity comes the potential for rack and inventory damage from various angles and situations. With that in mind, what are some simple ways you can protect your pallet rack?

Tags: Pallet Rack, rack safety, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

Ways to Pick Full Cases Faster, More Accurately and More Ergonomically

Case picking is common in most e-commerce, retail and wholesale distribution operations, so it’s important to understand the best ways to pick cartons from start to finish through a process. Most warehouse operations will need at least some case-picking capacity. Beverage and grocery distributors almost always need a large full case picking function. Since order picking commands a high percentage of distribution center labor costs, finding ways to make it more efficient is critical.

Tags: Automation

Posted in Order Picking & Fulfillment|

Bowing, Leaning and Out-of-Square Pallet Racks: Causes & Solutions

Racks will often be damaged over a long lifetime of use. When you see a bent beam, out-of-square beam, damaged upright or other issues with your pallet racks, you can’t ignore it.

Posted in Pallet & Warehouse Racks|

Choosing the Right Pallet Conveyor

Above: a powered roller conveyor transporting a heavy load at Simmons Pet Foods.

Pallet conveyors transport skids, pallets, sheets and other extremely heavy loads. This can be accomplished with chains, belts, rollers or even ball transfers. The pallet conveying solution is critical for efficient, speedy product or process flow. Given the options, which conveyor type is right for you?

Posted in Conveyor Optimization|

Pallet Rack Clearances: Lateral, Vertical and Building Structures

One of the critical aspects of pallet rack system design, aside from the specs of the rack itself, are the various clearances between rack components, the loads and the surrounding environment. Flue space can be critical for fire safety compliance. Space between a rack row and the row behind it can contribute to a safer and more effective rack system. Narrow aisles can contribute to accidents. Too tall? You could cause damaged and falling inventory, as well as damage to fixtures or HVAC components.

At the end of the day, the space around the rack is nearly as important as the rack itself.

Posted in Pallet & Warehouse Racks|

Shoptalk: Forklift Warning Lights

In this installment of Cisco-Eagle’s Shoptalk series, Missy, who works extensively with forklift safety lights and other accessories, discusses the different styles and types of forklift safety lights available, and how to choose the right light for your operation. Different styles of lights will bring you different levels of safety and protection. Missy lines out what each type of forklift light will do for you in this video.

Tags: Shoptalk

Posted in Safety & Ergonomics|