It ought to be fairly simple, but specifying the right workbench for your application is something that requires thought and pre-planning if you want to maximize your time and labor. Minor differences in the type of bench can provide critical benefits that add up to major productivity gains over time. Benches aren’t the simple, static equipment many believe. Here are some traits to consider.

Tags: workstations, ergonomics, workbenches, work bench, warehousing

Posted in Storage, Organization & Workstations|

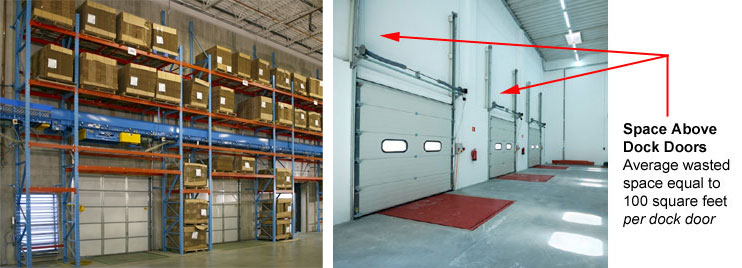

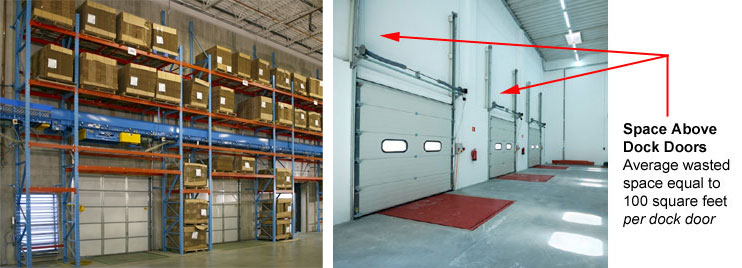

Next time you’re standing there wondering where you’re going to put an inbound shipment while your dock is stacked with empty pallets, look at those doors (or at the void above them) — the copious space between the top of the doors and the ceiling is unused. Multiply each door by that amount of space, and in many operations, we’re talking serious amounts of unused square footage.

The easy solution: find a use for it with over-dock-door storage. You can’t really rack heavy stuff up there without some significant structure. The best thing to consider is empty pallets, which take up a ton of room and are relatively lightweight. And usually, they’re all over the floor and always in your way. Empty pallets clutter up the shipping & receiving docks or can take up positions in your racks that would be better suited to full pallets of finished goods or incoming shipments.

Read the rest of this entry »

Tags: warehousing, Material Handling, Pallet Rack, space savings, industrial safety, dock doors, pallets

Posted in Space Optimization & Planning|

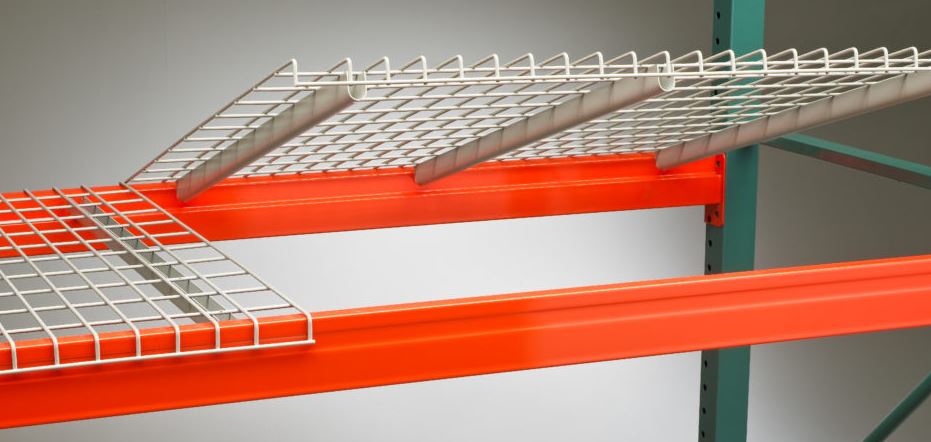

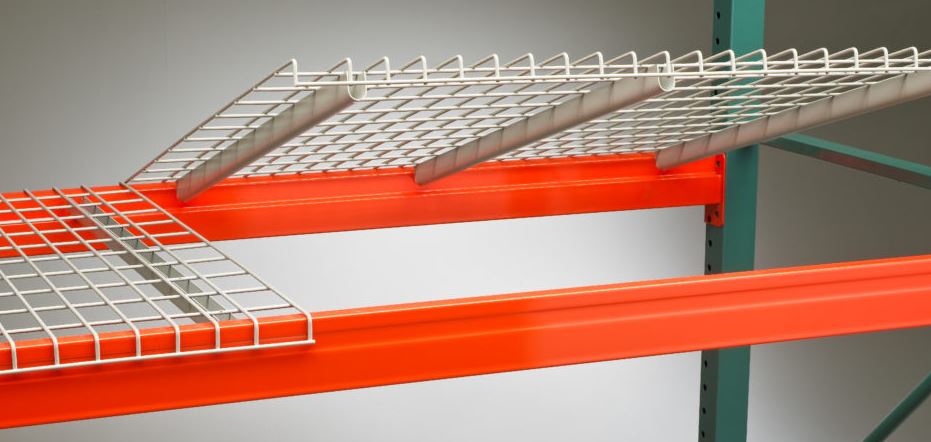

The Material Handling Industry of America recently announced that the RMI (Rack Manufacturers Institute) has certified several manufacturers of wire rack decking “R-Mark” compliant, meaning that these companies have conformed to the Institute’s testing and utilization standards.

Read the rest of this entry »

Tags: wire decking, industrial storage, warehousing, Material Handling, Pallet Rack

Posted in Pallet & Warehouse Racks|

At this time of the year, many companies find the need to maintain open access to dock doors and warehouses without letting heat and other environmental controls escape into the cold. The obvious solution has been to install vinyl strip doors, which allow easy access to foot and lift truck traffic while they also keep climate-controlled air in – and cold air out.

Read the rest of this entry »

Tags: strip doors, debris barriers, Supply Chain, warehouse safety, climate control, plastic strip doors

Posted in Docks & Shipping|

Since overloading is a common source of pallet rack collapses, (in fact misapplication, including capacity issues, is the top cause) it’s important to understand how much weight your rack – not just your beams – can bear.

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, rack capacity, safe rack loading

Posted in Pallet & Warehouse Racks|

When you are running an operation with lots of racking, it isn’t uncommon to have to replace an occasional upright or beam, or to add new bays onto an existing row. Sometimes you cannot avoid it, as the rack was purchased years ago, by someone else, or from a source you can’t even locate. It might be that you bought used rack and need to fill some gaps in, or it may be perfectly good, 10-year old rack that just needs some damaged components replaced.

This is done all the time, and although it isn’t an optimum situation for rack stability and safety, you can minimize the issues by following the following guidelines:

Read the rest of this entry »

Tags: beams, uprights, warehousing, Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

Safety in warehouses tends to be greatly about the interactions between forklifts, pallet racks, people and stored products. This list of rack safety tips is part of our ongoing efforts to help warehouses operate safely and efficiently.

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

Craig Chamberlain has an article over at the MHEDA Edge website that you need to read if you use pallet rack wire decking.

Here’s the money quote:

“Decking can, and often does, directly bear the total weight of the application’s load and transfers that load to the beams of the pallet rack. Regardless of the weight-bearing capacity of the rack’s beams, an improperly overrated deck can and will jeopardize the load-bearing capacity of the entire system and result in a failure.”

Read the rest of this entry »

Tags: wire rack decking, Material Handling, Pallet Rack, OSHA, warehouse safety, facilities maintenance

Posted in Pallet & Warehouse Racks|

Something we often recommend to save space for our clients is modular drawer storage — for certain operations, in particular those with components, assorted small parts, hardware, or even tool storage, we’re talking about recouping 50% -70% of floor space. Once people have ’em, they love ’em.

Something we often recommend to save space for our clients is modular drawer storage — for certain operations, in particular those with components, assorted small parts, hardware, or even tool storage, we’re talking about recouping 50% -70% of floor space. Once people have ’em, they love ’em.

But there is more than one way to skin that cat. You can configure different kinds of cabinets to do different jobs. There are hundreds of possible combinations of drawer styles and sizes. Another wrinkle is what happens when you can merge the drawers with steel shelving. It can be new, it can be some you are already using. It begs the question: when is it better to have a cabinet, and when is it better to use shelving and compartmentalized drawer inserts?

Read the rest of this entry »

Tags: tool storage, Industrial Shelving, small parts, modular storage, warehousing, Material Handling, security, space savings

Posted in Storage, Organization & Workstations|

Unguarded rack is dangerous if there are people working in the aisles below. Safety managers know this, insurance companies know it, and if you have rack in your facility, you probably know it too. You have probably seen pallets break. You’ve seen drivers make mistakes when loading & unloading. We’ve seen things fall. If you’ve been in the business any length of time, you may have walked into your warehouse in the morning to find a case of something from the fourth level split open on the floor.

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

Read our customer reviews

Something we often recommend to save space for our clients is

Something we often recommend to save space for our clients is