In this installment of Cisco-Eagle’s Shoptalk series, Tina, Sales Support for our Oklahoma City office, discusses how to keep high-value materials secure with rack enclosures.

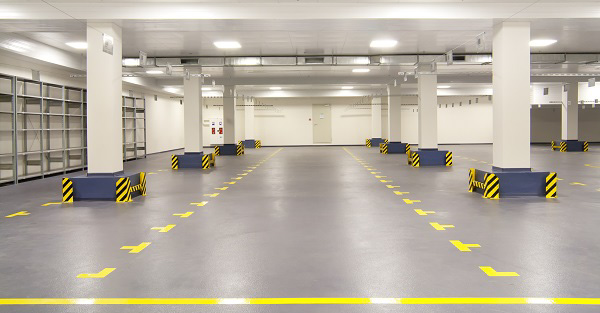

Spot The Mark – Why Floor Marking Is Essential

As we navigate this new age of Covid-19 and the distancing associated with it on all fronts of our lives, keeping areas within your facility safe and spaced becomes not only a priority now, but leads to further efficiency for operations in the future. Operations that utilize efficient means for creating visual clues within their warehouse showcase a more productive work environment that also keeps employees and equipment free from potential hazards.

One method to aid in this endeavor is floor marking. By marking areas in your facility, you highlight risks, outline areas for equipment and people, direct traffic and showcase safety considerations. In short, just by adding some color to your floor, you make your entire facility easier to navigate.

Posted in Space Optimization & Planning|

Tips for Better Drive-In Rack Specifications, Operations and Safety

When you need exceptionally high-density pallet storage, drive-in racks deliver space savings by eliminating forklift access lanes. They’re last-in, first-out storage ideal for stock that doesn’t need active inventory rotation and will be picked and used in a relatively fast manner. There are challenges to any storage system, of course. This guide should help you find ways to reduce the problems and operate your drive-in rack system more efficiently and safely.

Posted in Pallet & Warehouse Racks|

Putaway is Critical for Distribution Success

Above: workers in a distribution center putaway aisle with flow and bulk storage accessibility. Picking aisles are left clear as the system is replenished. Photo credit: Unex Manufacturing.

Putaway, which is the methods and processes that occur between receiving inventory and that inventory resting in storage positions in a warehouse, may have more impact on the performance of order fulfillment or warehousing operation than most anything else.

Tags: 3PL, Third Party Logistics, ecommerce

Posted in Order Picking & Fulfillment|

Half The World Away – Automated Storage and Social Distancing

In this new age of Covid-19, facilities all across the globe are working within ever-changing restrictions and prioritizing employee protection while keeping operations moving forward. Social distancing is a key component of this within any building, and those tasked with monitoring and implementing distancing within a workforce must create new ways to combat the spread. This challenge is tough to work within even the smallest of offices, let alone a large warehouse or distribution center. Reducing employee contact while maintaining thriving production is not easy, and requires continued vigilance and creativity.

When considering options for increased or maintained social distancing, utilizing an automated storage and retrieval system (ASRS) is a great option to help prepare your facility for the coming waves and for the automated future that lies on the horizon.

Posted in Automation, Labor & Efficiency|

How to Use Dockboards & Dockplates Safely and Effectively

Dock boards and dock plates are built to transition forklifts, pallet jacks, carts, people and other transportation methods between trailers and your warehouse dock area or staging floor. How can you be sure the transition between truck trailers and your dock is safe?

Tags: Safety & Ergonomics, ergonomics

Posted in Docks & Shipping|

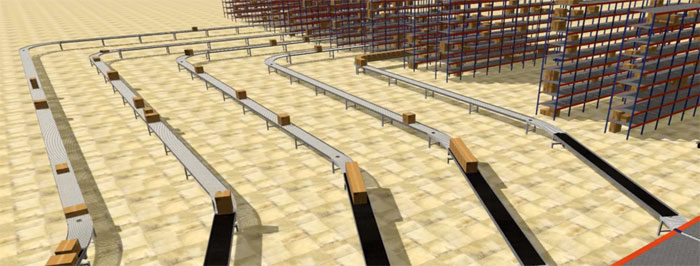

How Simulation Adds Value to Material Handling Systems Specification

As we’ve discussed automating anything as complex as a large scale material handling process has risks, but there are ways understand the outcome better in advance and reduce any risks. It’s always good to have more data, and simulation plays into that scenario by giving you a view of what key systems, technology and process will interact in your system, with your loads.

Tags: Factory Automation, ROI, data, simulation

Posted in Automation, Labor & Efficiency|

Shoptalk: How the Forklift Laser Tine Guide System Works

In this installment of Cisco-Eagle’s Shoptalk series, Rodney, Regional Director of Arkansas, discusses the benefits of using the forklift laser tine guide system.

Posted in Safety & Ergonomics|

Behind That Locked Door – Locker Cleanliness

As our new normal in the age of Covid-19 marches on, each facility is faced with balancing the ever-growing demand for products/services and keeping workers safe. Your environment must be clean and protect your employees every day to ensure not only the health and wellness of your workforce, but also an efficient and productive operation. New practices should be implemented to fight against this invisible enemy, whether it’s distancing or disinfecting.

With the continued easing of restrictions on how many people each facility may have on hand, you want to have a program in place that tackles all facets of employee safety. One area to target has one of the highest traffic rates and potential for infection–facility lockers.

Posted in Safety & Ergonomics|

Vertical Pallet Movement Options

In modern warehouses and manufacturing facilities, the vertical cube should be fully exploited, meaning that you should use overhead air space in your storage and processing operations because it’s less expensive and more efficient. Before you expand or relocate, it’s always better to use that space. You’ve already paid for it and the environmental costs of using it.

Using that space comes with some limitations. One is that you’ll need to transport pallets up to mezzanines or other machinery. While that’s more difficult than moving cartons or other lighter loads, there are ways. Let’s examine some of those options.

Posted in Mezzanines & Industrial Platforms|