The most common advice that ergonomics experts, OSHA, and other researchers provide to people in warehousing or other jobs that require manual lifting is that you should always bend your knees and lift that way, rather than bend at the waist to pick something up. Repetitive stress on the lower back is staggering: 20% of workplace injuries are related to lower back issues. Lifting right is essential to employee safety, and also to preventing Worker Compensation claims.

Even when you train employees to lift right – and we know that not everyone does – they frequently ignore the advice. Why?

Read the rest of this entry »

Tags: injury prevention, ergonomics, lifting, musculoskeletal, warehouse workers, back issues

Posted in Safety & Ergonomics|

Over at the Operations & Fulfillment site, Curt Barry has written a brief, informative piece on reducing warehouse costs. In particular during a difficult economic climate, cost reduction is at the top of mind for distribution operations.

Read the rest of this entry »

Tags: product slotting, warehouse productivity, ROI, labor management, distribution center

Posted in Warehousing & Distribution|

If you’ve ever stopped at a traffic light, and shuddered at the texting, teenage (or all too often, an adult) driver in the next lane, you probably thought this is an irresponsible person who shouldn’t be behind the wheel. Given statistics that smart phone users are impaired as drunk drivers, it’s a serious and deadly issue; most states have laws specifically forbidding texting on the road. The question is, do you tolerate that kind of distractions for forklift drivers in your warehouse? Should you have the same rules? (Short answer: yes).

Read the rest of this entry »

Tags: warehousing, Pallet Rack, forklift safety, distracted driving

Posted in Forklift - Pedestrian Safety|

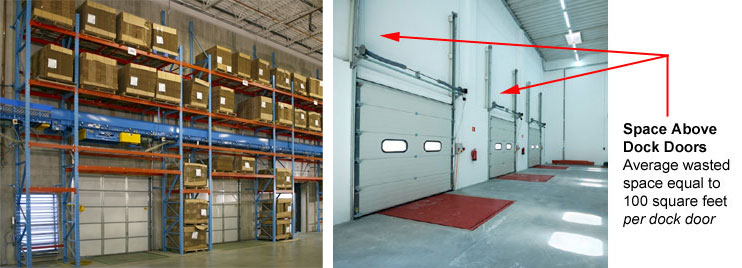

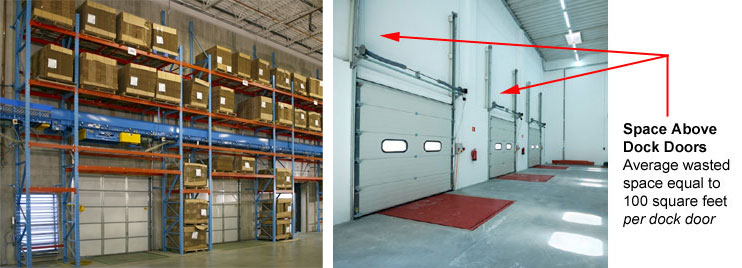

Next time you’re standing there wondering where you’re going to put an inbound shipment while your dock is stacked with empty pallets, look at those doors (or at the void above them) — the copious space between the top of the doors and the ceiling is unused. Multiply each door by that amount of space, and in many operations, we’re talking serious amounts of unused square footage.

The easy solution: find a use for it with over-dock-door storage. You can’t really rack heavy stuff up there without some significant structure. The best thing to consider is empty pallets, which take up a ton of room and are relatively lightweight. And usually, they’re all over the floor and always in your way. Empty pallets clutter up the shipping & receiving docks or can take up positions in your racks that would be better suited to full pallets of finished goods or incoming shipments.

Read the rest of this entry »

Tags: industrial safety, dock doors, pallets, warehousing, Material Handling, Pallet Rack, space savings

Posted in Space Optimization & Planning|

Leaving a dock door open all day is an invitation to have someone stroll your aisles, check out your inventory, and perhaps take something. Most busy operations, particularly in good weather situations, leave those doors open. Often, the crew is busy with actual work; they don’t have the time to monitor visitors, delivery drivers, service providers, and every other person who strolls in.

Read the rest of this entry »

Tags: Material Handling, security, wire security cages, Industrial Security, wire partitions

Posted in Docks & Shipping|

This is a series of posts we’ll be making about saving space in your facility. There are plenty of ways to better utilize space, and some of them might fit your circumstances while others certainly won’t. In today’s challenging business climate, it is particularly critical to use space wisely in your facility.

Read the rest of this entry »

Tags: modular storage systems, warehousing, materials handling, saving space

Posted in Space Optimization & Planning|

In dynamic distribution environments, accurate, fast weighing, counting, and dimensioning systems are more important than ever. This is particularly true in 3PLs and other operations where needs often change. Getting it right, and getting it quickly has become increasingly more important. One way is to utilize the newer mobile weighing systems on the market today.

Read the rest of this entry »

Tags: warehousing, Material Handling, scales, industrial weighing systems, inventory accuracy

Posted in Warehousing & Distribution|

There are many issues of productivity and safety that are stressed as the heat rises. As temperatures start to rise, it gets particularly hot in industrial facilities, warehouses, shops, and distribution centers where air conditioning isn’t always present, extremely costly, or very effective. Experts say that employee productivity increases when ambient temperatures are comfortable and plummets when they aren’t. Error rates climb and safety is compromised as workers fight through hot, sweaty conditions. Here are some ways you can go about combating the rigors of summer.

Read the rest of this entry »

Tags: Conveyor, warehousing, Material Handling, industrial safety, heat stress, heat exhaustion, industrial fans, climate control, fans

Posted in Safety & Ergonomics|

This month, we discuss strategic warehouse execution system implementations with Savoye–how to scale, how to match real-world processes. Additionally, the impact of employee ownership on manufacturing and its potential as a key to succession for small and mid-sized manufacturers. Also, more on industrial construction and the softening demand for manufactured products.

Read the rest of this entry »

Posted in Industry Insights|

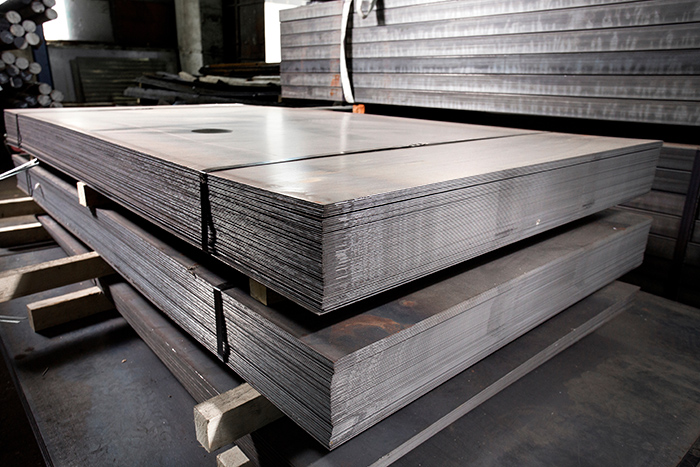

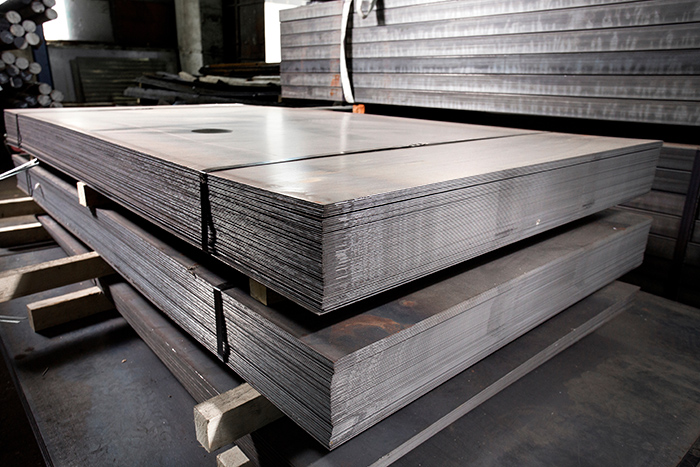

Whether you’re running a metal fabrication shop or laser cutting center, or stocking raw materials for manufacturing, sheet metal storage can make you faster. It makes the stock easier to reach, protects valuable materials and prevents injuries. However, the wrong solution means injuries, wasted time and damaged materials. In this article, I’m covering a range of solutions, from simple floor stacking to semi-automated carousels, analyzing for fit, safety, access and cost.

Read the rest of this entry »

Posted in Manufacturing|

Read our customer reviews