Adjustable workstations make operations like packing, picking, assembly and inspection safer, more comfortable and more productive because they easily let operators work in the ergonomic “golden zone” suitable for their own needs – the same station can be used by someone 6’4″ as someone 5/2″ on multiple shifts, or if the load or work varies in height, like multiple sized boxes or various motors that may be different sizes. These workbenches are adjustable, usually by crank or by powered switch or pushbutton. What might suit you best?

That said, having to utilize a crank to adjust the height is inherently counter to the fundamentals of ergonomics, and it’s slow. To combat this, consider electric adjustable workstations, which provide multiple advantages over their cranking counterparts.

Read the rest of this entry »

Tags: Safety & Ergonomics, Warehouse Management, warehousing, warehouse, workstations, ergonomics, plant safety, forklift safety

Posted in Storage, Organization & Workstations|

Above: SAS Automation standardized bag-gripper

Palletizing is a standard material handling application for industrial robots, and bag palletizing is one of the most typical applications. Why? Because bag palletizing is simpler and easier than case palletizing. If your operation requires bag stacking/pallet loading – and you want to improve speed, reduce mistakes, and create a more ergonomic system, here are the things you need to know.

Read the rest of this entry »

Tags: ergonomics, Robotics, labor

Posted in Automation, Labor & Efficiency|

When working with palletized goods stored at floor level beneath a rack beam in a typical warehouse, there are significant issues for order pickers who execute these tasks daily, including strains and stresses that can lead to major injuries, down time, and worker compensation expenses.

Read the rest of this entry »

Tags: ergonomics, Safety & Ergonomics, rack bumper, rolling pallet, pallet truck, positioner

Posted in Safety & Ergonomics|

Providing employees with a comfortable, ergonomic, and efficient workspace is a necessity in any picking, packing, assembly, inspection, quality control, manifesting or other industrial operations. A proper industrial workstation, tailored to the task and employee, goes a long way toward creating a healthier and more productive workspace and environment.

There are dozens of options for workstations, ranging from a simple bench to a more elaborate set up designed with the job in mind. Let’s take a look a few industrial workstations and their unique benefits.

Read the rest of this entry »

Tags: workstations, ergonomics

Posted in Storage, Organization & Workstations|

I recently attended a product training class on high volume low speed fans, and a statistic was thrown out to the audience that really got me thinking. A NASA study, Compendium of Human Responses to the Aerospace Environment*, showed that worker productivity falls significantly for every degree over an optimum temperature of about 72 degrees. If the temperature hits 85 degrees in the workplace, productivity drops by 18% and accuracy a walloping 40%.

Read the rest of this entry »

Tags: ergonomics, Safety & Ergonomics, worker environment, temperature comfort, fire safety, air quality, hearing loss, noise, lighting quality

Posted in Safety & Ergonomics|

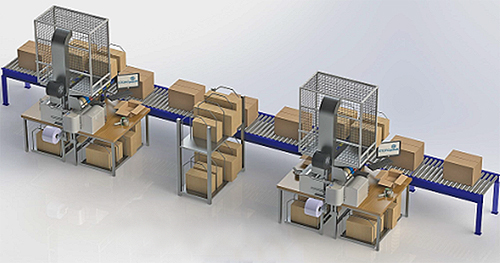

As your business grows, the flow of materials tends to bog down as demand increases, forced through the same channels and processes. Throughput grinding slowly down is a story as old as warehousing itself.

Frequently the operations that lag behind the rest of the process are in the picking, packing and shipping areas of your facility. What’s difficult is that these inefficiencies evolve over time, where they can almost be hidden from an analytical view. It seems that no matter how many people you throw at the problem, they never catch up, and error rates escalate. Often the solution is in simple steps toward organizing your packing areas and putting supplies conveniently at hand.

Read the rest of this entry »

Tags: shipping, workstations, ergonomics, industrial work stations, workbench, warehouse flow, throughput, packing

Posted in Storage, Organization & Workstations|

Industrial workplace safety bears repetition and consistent reinforcement

For manufacturing and distribution operations, workplace safety doesn’t just protect workers—it optimizes productivity and helps drive revenue growth. It also helps protect company assets, reduces downtime, and increases morale. What can you do to protect your employees in picking, packing, material handling, assembly, maintenance and similar work? To answer this question, we spoke with leading manufacturers and distributors. Here’s what they had to say: Read the rest of this entry »

Tags: WireCrafters, Hytrol, industrial safety, Unex, ergonomics

Posted in Safety & Ergonomics|

Everyday functions of most warehouses and industrial operations fall within the realm of manual material handling–constant lifting, bending, stretching, reaching, pushing and otherwise manipulating materials by physical force. People are moving cartons, picking orders, reaching for packing materials and performing other tasks. Manual material handling contributes to musculoskeletal disorders, to the tune of more than 500,000 reported annual reported cases of strains and stress in shoulders, backs, arms and legs.

While you can never eliminate it, you can reduce the worst aspects of it. Let’s dive into some ways.

Read the rest of this entry »

Tags: industrial safety, ergonomics, lifting, manual material handling, musculoskeletal

Posted in Safety & Ergonomics|

In the last 200 years 70% of jobs done by American workers have been replaced by automation – and during the next century we will see another automation revolution that replaces 70% of American jobs–again.

Tags: Automation, ergonomics, Safety & Ergonomics, Robotics, workers force

Posted in Automation, Labor & Efficiency|

I recently attended an ESOP event at a specialty paints and stains company. During the tour of their plant, I got to see a robotic palletizing system in operation. I was impressed. Standing about 6 to 8 feet away from the action, I watched as it placed 5-gallon cans of paint in rows of 3 stacked 3 high. Each row was offset from the previous one, so that optimum pallet space was used. As the robot picked up cans off the conveyor belt using a vacuum end effector, it placed them precisely on the pallet. Then, it slightly dropped down and “bumped” them to make sure they seated onto the row below. That action made me chuckle as I considered what a profoundly human act that was – a little hip action to make sure the cans seated correctly.

Read the rest of this entry »

Tags: industrial safety, palletizing, ergonomics, Robotics, Time-savings, lean manufacturing

Posted in Automation, Labor & Efficiency|

Read our customer reviews