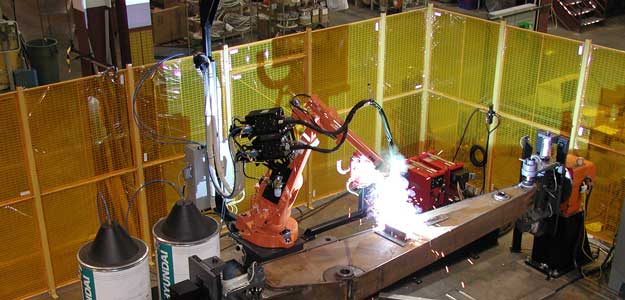

In this new age of warehouse or facility labor shortage, more and more companies are turning to automation and robotics to help fill in the gap and increase productivity as well. With e-commerce showing no signs of slowing and innovative supply chains being rewarded, you can bet that companies embracing this new dawn are showing better ROI and efficiency. One aspect of adopting robotic help for your warehouse to review is that of safety. While the overall safe environment you provide to your operations is crucial, when adding robotics or automation to the mix it requires a new set of ideas and priorities to ensure your workers and ‘bots can coexist.