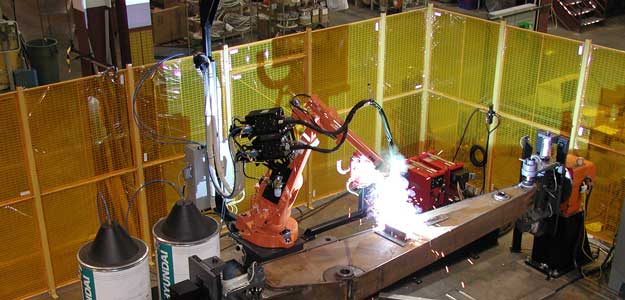

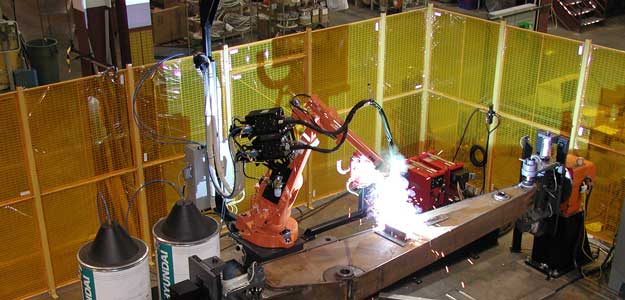

In this new age of warehouse or facility labor shortage, more and more companies are turning to automation and robotics to help fill in the gap and increase productivity as well. With e-commerce showing no signs of slowing and innovative supply chains being rewarded, you can bet that companies embracing this new dawn are showing better ROI and efficiency. One aspect of adopting robotic help for your warehouse to review is that of safety. While the overall safe environment you provide to your operations is crucial, when adding robotics or automation to the mix it requires a new set of ideas and priorities to ensure your workers and ‘bots can coexist.

Read the rest of this entry »

Tags: Robotics, Safety & Ergonomics

Posted in Automation, Labor & Efficiency|

Material handling installations can be complicated by nature.

Shipments are coming from multiple sources, arriving at different times. Subcontractors from electrical installers to controls to cleaning crews must be coordinated. Layouts and concepts must be implemented on time, even as deadlines change while issues are being resolved. At the end of the process, the system must be commissioned and the people who will work in it trained. Maintenance and spare parts will be dealt with.

Read the rest of this entry »

Posted in Automation, Labor & Efficiency|

Return-on-investment is critical to automation projects, but justification isn’t straightforward. If you’re trying to convince management to make capital improvements to your operation, a smart, accurate and succinct ROI summary can work wonders. Let’s dive into some methods you can use to understand what to do — and what you can’t quantify.

Read the rest of this entry »

Tags: Automation, labor, ROI, Robotics

Posted in Automation, Labor & Efficiency|

With e-commerce operations moving at an ever-increasing pace, you must take every advantage to meet consumer expectations. You not only want to save the customer time on their order, but also gain manufacturing and processing time by doing so. With careful consideration and a robust process, each aspect at play in a distribution center or warehouse could be an opportunity to save seconds.

To maximize every advantage, more facilities are turning towards automation to meet those strong demands. By utilizing automation, a distribution center can provide a more flexible and efficient environment in addition to more accurate orders delivered on time. The ability to scale and grow with automation is also an attractive one. But to jump headfirst into the automation process is a daunting task, and can cause an operations manager cause for concern. Two overlooked areas that can become a “tipping point” for this process are mezzanines and VRCs.

Read the rest of this entry »

Tags: vrc, mezzanine, vertical reciprocating, Mezzanines

Posted in Automation, Labor & Efficiency|

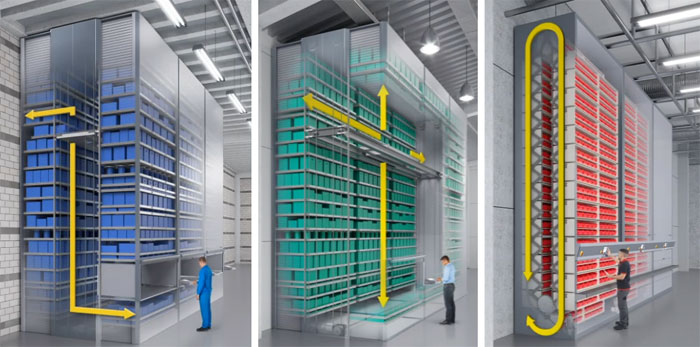

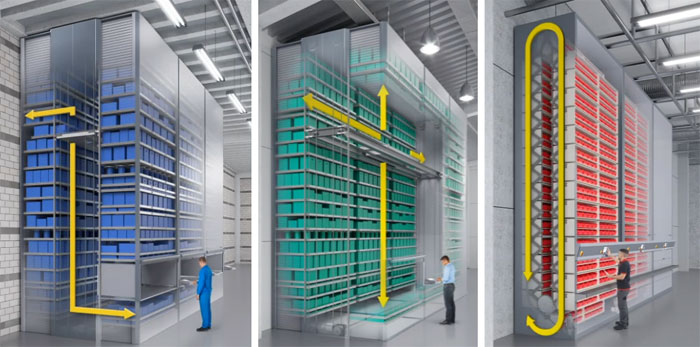

Once an afterthought in the warehouse, vertical carousels are being reborn in the omnichannel age as a fulfillment finish line product. Retailers are eyeing carousels to help them aid in customer retrieval of picked orders shipped to a retail location, which is giving the carousel a “moment” as a new last-mile darling. Whether located in the back of the store for employees to use, or at the front for customers to pick up themselves, vertical carousels are showing to be a good fit for this new age of sales. But don’t sleep on their value in industrial settings or distribution channels.

Read the rest of this entry »

Tags: vertical carousel, industrial carousels, ecommerce

Posted in Automation, Labor & Efficiency|

The advantages of pick-to-light for order fulfillment are well-documented: you can pick faster and more accurately without the burden of tickets or voice-activated systems. Your workforce can be trained in a fraction of the time, in a “fast food” type experience. It’s a technology that has found broader applications in many distribution centers simply because it’s a fast, easy way to improve.

Light-directed systems may have a more positive impact on assembly than they do on order picking.

Read the rest of this entry »

Posted in Automation, Labor & Efficiency|

A research paper was released last month by two Harvard labor economists highlighted one of the coming decade’s most interesting talking points: the automated labor of the future. We are no strangers to the unique opportunities that adding robots can provide. What this paper sought to do was estimate the current effect of the introduction of robots on wages and employment, while also focus on the future they pose in industrial and manufacturing economies.

With this kind of research being conducted (with many more studies to be revealed for sure) and a spotlight put on the future robotic workforce, many with facilities that could use their services would be wise to discover how they can benefit. But what, exactly, should you be looking for?

Read the rest of this entry »

Tags: labor, Robotics

Posted in Automation, Labor & Efficiency|

While warehouse robotics can be thought of as too futuristic, there are many e-commerce fulfillment applications being installed today that are set up to take full advantage of all they have to offer a facility. Some may be leery of this technology, but it would be a mistake to say that robotics would never apply to your warehouse.

Today’s robotic applications are all based on existing applications and technology, not uncharted research, and each generation of technology gets cheaper. Here are some important considerations when looking at applying warehouse robotics today.

Read the rest of this entry »

Tags: warehouse flow, Manufacturing, e-commerce, Robotics

Posted in Automation, Labor & Efficiency|

When you consider the various storage media and order picking methods, it’s critical to understand why some items are better picked in a variety of storage media, and accessed by the right type of picking authentication. The following table is a visual comparison of these alternatives.

Read the rest of this entry »

Posted in Automation, Labor & Efficiency|

With the rapid increase of the pace of manufacturing and distribution, facilities that automate manual processes will increase their ROI and grow their bottom line. Customer demand is ever increasing, right along with the costs to service that demand. You want your warehouse to deliver faster and more efficient results without sacrificing production. You’re looking at automating components within your facility to produce this change. But how can you really get started?

Read the rest of this entry »

Tags: Supply Chain, Manufacturing, distribution center, e-commerce, warehouse productivity, Warehouse Management, warehousing, Material Handling

Posted in Automation, Labor & Efficiency|

Read our customer reviews