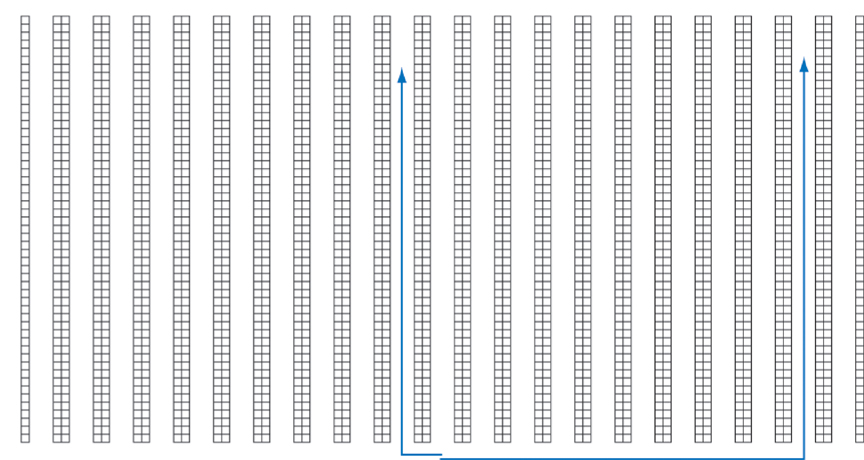

As a business grows, usually storage demands also increase, leaving you facing choices like storing goods off-site, relocating to larger facilities, or turning to a third party for warehousing or distribution – choices that increase overhead costs year over year. What if you could avoid those choices and increase available space in your existing storage by removing the aisles between the rows of racking and shelving?