When I was a kid, on rainy days my friends and I used kitchen chairs, old blankets and lots of clothespins and built our own special space for imaginary adventures. Our rag-tag shelter was temporary, but gave us the sensation of being in our own little world. Frequently, in manufacturing and warehousing facilities, work zones and independent departments need separation from the larger whole for either safety or autonomy purposes, and there are products out there that answer those needs. Products like curtain walls, acoustic walls, thermal barriers and welding screens. Read the rest of this entry »

Curtains and Dividers Help Retain Climate, Protect Products

Tags: thermal, strip door, plastic, vinyl, welding, screen, warehouse space savings, curtain walls, acoustic, barrier

Posted in Safety & Ergonomics|

Order Picking: Optimizing and Storing Slow Movers

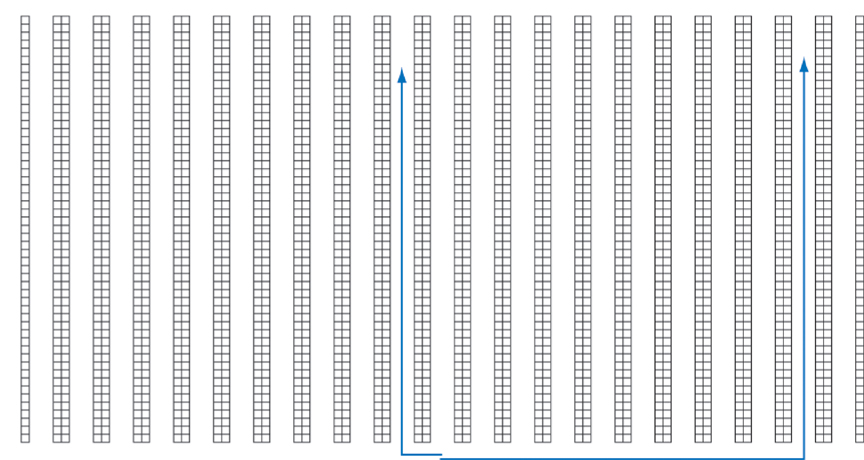

The focus when it comes to order picking is usually (and justifiably) on the fastest-moving product. You slot your warehouse for fast movers. You pareto-focus on the 20% of the product that generates 80% of the business, as you should. But it’s also useful to consider the slow-moving inventory and pick locations. Simply putting the slowest movers in the least accessible area may make them consume more order picking time and storage space than necessary.

Tags: order fulfillment, Industrial Shelving, carton flow racks

Posted in Order Picking & Fulfillment|

Innovations in High Density Storage

Ever find yourself wondering how you can get more out of your pallet rack? Do you have goods that take up very little space, but your pick operations don’t call for entire pallets full of the product? Then you might need to look at ways to achieve more density in your storage, and we’ve recently found a gem of a product that can help you out. It’s called Dynamic High Density Storage and it’s made by SpeedCell.

Tags: space savings, storage, industrial storage, distribution center, Order Picking & Fulfillment, Warehouse Management, warehousing, Pallet Rack, order fulfillment, warehouse storage

Posted in Pallet & Warehouse Racks|

5 Heavy-Duty Shelving Solutions to Help You Maximize Storage Capacity

When it comes to the storage of industrial equipment, products, and parts, you need a reliable heavy-duty solution. Whether you work in a warehouse, shop, office, or manufacturing facility, a proper system of organization is essential to the way that you keep records, manage inventory, solve problems, and care for your tools.

Here’s a look at 5 industrial shelving solutions that can help you maximize your facility’s storage capacity, ultimately resulting in greater efficiency and workplace productivity: Read the rest of this entry »

Posted in Storage, Organization & Workstations|

Avoid Common Warehouse Layout Mistakes

It’s not easy to understand when facility layout is causing significant problems for an operation.

The way the warehouse is planned and laid out can affect everything in a warehouse or distribution facility. You may be suffering from over-forecasted demand for product and under-forecasted need for square footage. Executives may not fully understand what it takes to receive, store and ship orders. What are some of the more common problems when it comes to facility layout?

Tags: Third Party Logistics, facility layout, ecommerce, 3PL, warehouse storage

Posted in Space Optimization & Planning|

Warehousing Key Performance Indicators

Key performance indicators – KPI’s – are frequently used in general business to evaluate the success of everything from a specific department to an entire enterprise. They focus on strengths and weaknesses. Many warehousing KPI’s tend to be focused on external performance, such as on-time shipments that directly impact customers. This is a good measure, but the need to go deeper and measure the factors that drive those success rates is critical. What are some KPI’s for warehousing operations?

Tags: measurements, ROI, shipping & receiving, KPI, benchmarking

Posted in Warehousing & Distribution|

The Case for a “Supersized” Receiving Area in Your Warehouse

Receiving is an often-overlooked but critical component to warehouse workflow. Receiving mistakes can flow through every other aspect of your operation.

If you can’t quickly and accurately break down landed shipments and send them to effective putaway, you can sabotage every other aspect of the operation. It has a direct impact on inventory accuracy (and security – in fact receiving is an area of particular vulnerability), throughput, and accurate fulfillment. Too little receiving space tends to become a root cause for many errors and throughput headaches.

Posted in Docks & Shipping|

A Quick Guide to Order Picking Methods & Productivity

When you work on order picking strategies, knowing the metrics for picking rates may be helpful. Labor productivity is the key to any warehousing or order picking operation, since labor tends to be the largest single cost factor in these operations. It’s critical to understand production rates for processes that absorb labor hours, energy, money, and time.

Posted in Order Picking & Fulfillment|

Tactics to Reduce Small Parts Order Picking Errors

Small parts are more difficult to count, measure and handle. They tend to cause more errors than case picking or larger component orders. If you are having errors, you should try to define the causes — and the suspects abound. Can you find out what’s causing the errors? Once you do, what happens next? Here are some common causes and solutions to this issue.

Tags: lean warehousing, Order Picking & Fulfillment, 5S principles, error reduction

Posted in Order Picking & Fulfillment|

The Top 10 Do’s and Don’ts of Safe Conveyor Operations

Conveyor safety should always be a top concern. With more than 50 workplace fatalities a year where conveyors are the primary source of injury and workplace accidents accounting for nearly 25% of all workers’ compensation claims, you must pay attention to industry standard safety practices.

Tags: Safety & Ergonomics

Posted in Conveyor Optimization|