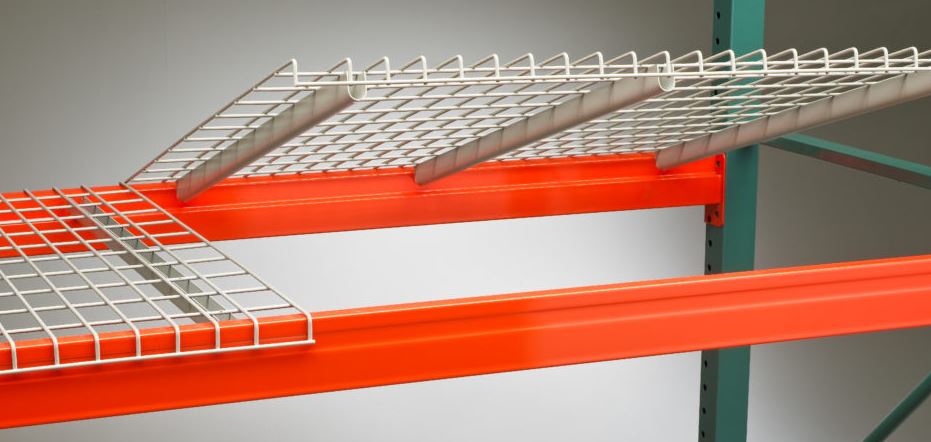

Push back rack systems are excellent high density storage solutions — perhaps the most economical way to squeeze space out of a crowded warehouse. All loads are stored and retrieved from the same aisle. This reduces the number of aisles needed in a facility, freeing up more space for storage. Aisles can take a great deal of space up in a typical warehouse, so by implementing a pushback pallet rack system, you essentially swap selectivity for space. Push back rack systems provide a Last-In-First-Out (LIFO) inventory rotation, so you have to be certain your load fits. If it does, congratulations — you’ve just saved a lot of space.

But there are issues that can arise when pushback rack is inappropriately specified or utilized.