Conveyors are often installed overhead or suspended from the ceiling to help conserve floor space or to interface with mezzanines or platforms. This may create potential fall hazards. Loads can fall from inclined conveyors as they are conveyed up or down, or be subject to other factors that can cause a fall from an elevated line. Even on a floor-mounted conveyor, a spill can split a case, land on an order pickers’ toes, or damage inventory.

Read the rest of this entry »

Tags: fall protection, Belt Conveyors, guard rails, conveyor safety

Posted in Conveyor Optimization|

Industrial workplace safety bears repetition and consistent reinforcement

For manufacturing and distribution operations, workplace safety doesn’t just protect workers—it optimizes productivity and helps drive revenue growth. It also helps protect company assets, reduces downtime, and increases morale. What can you do to protect your employees in picking, packing, material handling, assembly, maintenance and similar work? To answer this question, we spoke with leading manufacturers and distributors. Here’s what they had to say: Read the rest of this entry »

Tags: Hytrol, industrial safety, Unex, ergonomics, WireCrafters

Posted in Safety & Ergonomics|

Somewhere in your facility, there may be a place where someone frequently shouts “shut the door!”

Perhaps you have operations that require maintaining temperatures within certain limits. There may also be areas heavy-traffic areas where a conventional overhead door’s slow lift and close rates cause delays, slower throughput and cause reduced productivity from waiting on a door to open.

These are situations where a high-speed door may solve a variety of problems. From limiting airborne debris, dust and contaminant infiltration to temperature regulation, high-speed doors pick up the pace in your facility even as they limit the amount of exposure to negative environmental influences. They open and close so quickly that forklifts and people hardly need wait on the door in order to pass through the doorway. Let’s take a few minutes to explore the types and key features of high-speed doors.

Read the rest of this entry »

Tags: collision, forklift, high-speed door, vinyl mesh door, aluminum frame, steel frame, stainless steel frame, self-repair

Posted in Docks & Shipping|

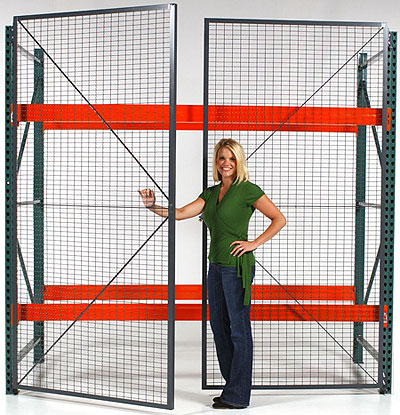

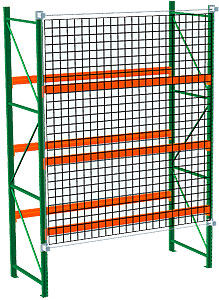

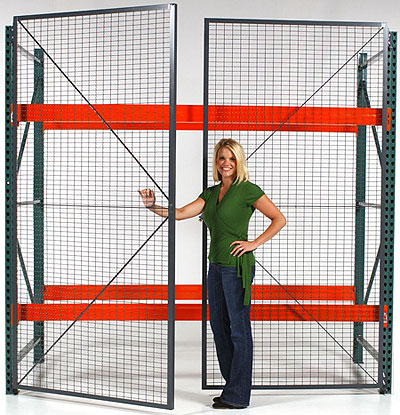

Warehouse security is sometimes slighted – other than perhaps exterior door locks and perhaps alarms. Security professionals will tell you that security is substantially about access to desirable items. How can you limit it? Let’s take a look at security equipment that can reduce temptation and help to keep vandals away from expensive exterior equipment.

Read the rest of this entry »

Tags: expanded steel, security cabinet, truck, security products, wire cage, wire partition, woven, welded, mesh

Posted in Security|

Carton flow expedites pick operations by making stock accessible in an easily replenished first-in/first-out pattern. Gravity flow racks can reduce labor costs up to 75% in pick operations compared to static storage picking by delivering cartons and split case goods to the pick aisle rather pickers pulling from the static pallet rack storage. It is a commonly used storage/picking method in many operations, but there are many options and types of flow storage available. Which fits your need best?

Read the rest of this entry »

Tags: pick shelving, mobile tilt shelving, rail flow, gravity carton flow, roller track, skate wheel bed flow

Posted in Order Picking & Fulfillment|

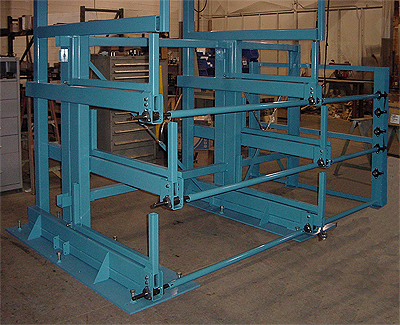

Steel guard rail is one of the best–and most economical–accident prevention tools in a facility’s safety arsenal. It helps keep workers safe from forklift traffic, protects valuable equipment from potential damage, and even guards ends of pallet rack rows. But there may be times when you need forklift or cart access to protected areas (or simply don’t want to step over or around railing). How do you handle those situations? How often are you having to remove your guard rail and then reassemble? There’s a better way available — lift-out rail systems.

Read the rest of this entry »

Tags: Lift-out guard rail, lift-out/drop-in, drop-in, access point, lift-out, guard rail systems

Posted in Safety & Ergonomics|

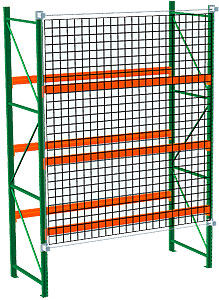

When approaching pallet rack choices, cost, storage density and construction elements all play a role in making a choice. While cost is always a prime concern, be mindful that cost is often tied to storage density. Cheaper pallet rack tends to not have as much storage density as more expensive rack. But before you consider cost, you must decide what applications you will use the pallet rack for.

Read the rest of this entry »

Tags: gravity flow rack, selective pallet rack, structural, seismic, mobilized

Posted in Pallet & Warehouse Racks|

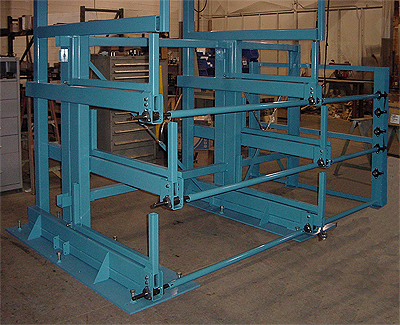

If you’ve got conduit, tubing, rebar, pipe or bar stock, you need cantilever rack – period. Get it off the floor, off of standard shelving and pallet rack, and put it somewhere you don’t have to fight with it each time you need some. If you’re really smart, you’ll put it where overhead lift equipment can get to it – because once you get it stored right, you’ll wonder what the heck you were thinking earlier.

Read the rest of this entry »

Tags: Safety & Ergonomics, cantilever rack, crank out shelving, ergonomic, heavy duty cantilever rack

Posted in Pallet & Warehouse Racks|

People store all kinds of things on pallet rack – from truck engines to fine jewelry. How do you protect valuable goods from being accessed by unauthorized personnel? What about inventory toppling off the back of the rack into an aisle where workers are?

Read the rest of this entry »

Tags: Pallet Rack, warehouse safety, Pallet Rack Safety Netting, Rack Security Cages

Posted in Pallet & Warehouse Racks|

All too often, companies struggle because the size of their warehouse is considered in the planning stage, but not the efficient use of that space.

A facility is purchased or leased with the desired set of characteristics, and then work begins. There are significant opportunities in many operations to size up the business mix, order trends, product slotting and facility layout in a way that helps improve everything from storage density to pick rates to error rates to labor costs. But first we must know the total storage potential of the facility, and work backwards from there.

Read the rest of this entry »

Tags: warehouse storage, storage space, facility layout

Posted in Space Optimization & Planning|

Read our customer reviews