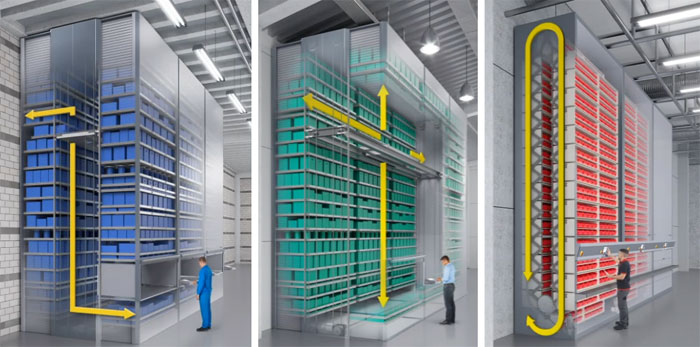

Pushback rack systems provide a unique way to gain more space in a crowded warehouse. They store pallet loads on both sides of an aisle at higher cubic densities, approximately 25% to 65% greater than selective racking. What that means is loads can be stored and retrieved from the same aisle, reducing the number of aisles needed. Freed space, that’s the name of the game with pushback rack.