In modern warehouses and manufacturing facilities, the vertical cube should be fully exploited, meaning that you should use overhead air space in your storage and processing operations because it’s less expensive and more efficient. Before you expand or relocate, it’s always better to use that space. You’ve already paid for it and the environmental costs of using it.

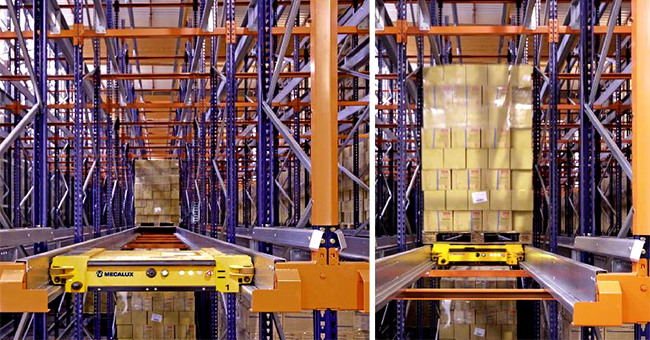

Using that space comes with some limitations. One is that you’ll need to transport pallets up to mezzanines or other machinery. While that’s more difficult than moving cartons or other lighter loads, there are ways. Let’s examine some of those options.