In this installment of Cisco-Eagle’s Shoptalk series, Tina, Sales Support for our Oklahoma City office, discusses how to keep high-value materials secure with rack enclosures.

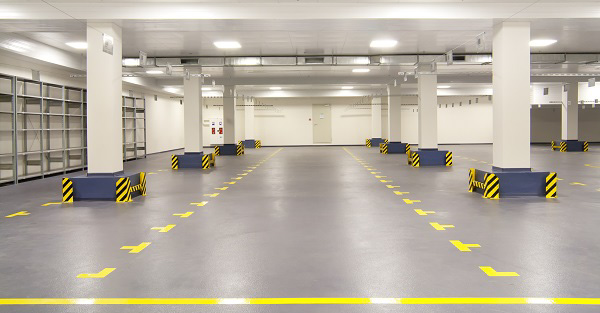

Why Floor Marking Is Essential

As we navigate this new age of Covid-19 and the distancing associated with it on all fronts of our lives, keeping areas within your facility safe and spaced becomes not only a priority now, but leads to further efficiency for operations in the future. Operations that utilize efficient means for creating visual clues within their warehouse showcase a more productive work environment that also keeps employees and equipment free from potential hazards.

One method to aid in this endeavor is floor marking. By marking areas in your facility, you highlight risks, outline areas for equipment and people, direct traffic and showcase safety considerations. In short, just by adding some color to your floor, you make your entire facility easier to navigate.

Posted in Space Optimization & Planning|

Warehouse Bins & Containers Specification

Most warehouses use bins, cartons or containers as bulk product shipments are broken into “eaches” or smaller quantities for putaway, storage and eventual picking. This is also largely true of assembly and manufacturing lines where components are transported between workstations and work is progressively done. While they don’t exactly break the bank given their costs, specifying the wrong container can result in a less efficient, less ergonomic operation.

Posted in Storage, Organization & Workstations|

Tips for Better Drive-In Rack Specifications, Operations and Safety

When you need exceptionally high-density pallet storage, drive-in racks deliver space savings by eliminating forklift access lanes. They’re last-in, first-out storage ideal for stock that doesn’t need active inventory rotation and will be picked and used in a relatively fast manner. There are challenges to any storage system, of course. This guide should help you find ways to reduce the problems and operate your drive-in rack system more efficiently and safely.

Posted in Pallet & Warehouse Racks|

Download Our Guide To Safe, Efficient Loading Dock Operations

Loading docks are critical because they’re where everything is received—and eventually shipped. The right shipping & receiving setup means smooth product flow, faster putaway and more accurate fulfillment. In short, it means a safer and better operation. To help you protect your docks and your people, check out our new dock equipment guide.

Posted in Docks & Shipping|

Putaway is Critical for Distribution Success

Above: workers in a distribution center putaway aisle with flow and bulk storage accessibility. Picking aisles are left clear as the system is replenished. Photo credit: Unex Manufacturing.

Putaway, which is the methods and processes that occur between receiving inventory and that inventory resting in storage positions in a warehouse, may have more impact on the performance of order fulfillment or warehousing operation than most anything else.

Tags: 3PL, Third Party Logistics, ecommerce

Posted in Order Picking & Fulfillment|

How to Use Dockboards & Dockplates Safely and Effectively

Dock boards and dock plates are built to transition forklifts, pallet jacks, carts, people and other transportation methods between trailers and your warehouse dock area or staging floor. How can you be sure the transition between truck trailers and your dock is safe?

Tags: ergonomics, Safety & Ergonomics

Posted in Docks & Shipping|

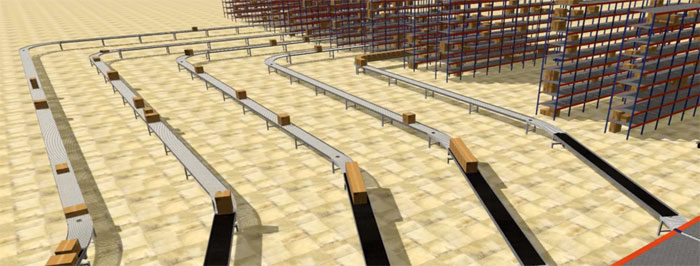

How Simulation Adds Value to Material Handling Systems Specification

As we’ve discussed automating anything as complex as a large scale material handling process has risks, but there are ways understand the outcome better in advance and reduce any risks. It’s always good to have more data, and simulation plays into that scenario by giving you a view of what key systems, technology and process will interact in your system, with your loads.

Tags: Factory Automation, ROI, data, simulation

Posted in Automation, Labor & Efficiency|

Shoptalk: How the Forklift Laser Tine Guide System Works

In this installment of Cisco-Eagle’s Shoptalk series, Rodney, Regional Director of Arkansas, discusses the benefits of using the forklift laser tine guide system.

Posted in Safety & Ergonomics|

Warehouse Automation Risks to Avoid

Automation can work wonders. It reduces costs, increases throughput, curbs errors and increases safety. The costs of automation are declining while the effectiveness of computer, vision and scanning systems are improving. Automation helps you reduce repetitive actions — the kind that adds no value. The common perception is that automated facilities are dark, free of people and full of robots, but the reality is that automation comes in many forms, ranging from picking systems like pick-to-light to automated conveyors to goods-to-person systems and much more.

For all these benefits, you want to understand the potential problems with any automation project in advance so you can avoid them as you move forward.

Posted in Automation, Labor & Efficiency|