There are many issues of productivity and safety that are stressed as the heat rises. As temperatures start to rise, it gets particularly hot in industrial facilities, warehouses, shops, and distribution centers where air conditioning isn’t always present, extremely costly, or very effective. Experts say that employee productivity increases when ambient temperatures are comfortable and plummets when they aren’t. Error rates climb and safety is compromised as workers fight through hot, sweaty conditions. Here are some ways you can go about combating the rigors of summer.

Tips to Fight Summer Heat in the Warehouse

Tags: climate control, fans, Conveyor, warehousing, Material Handling, industrial safety, heat stress, heat exhaustion, industrial fans

Posted in Safety & Ergonomics|

Comparing Pallet Rack Guards: Flexible Netting vs. Wire Mesh Panels

Unguarded rack is dangerous if there are people working in the aisles below. Safety managers know this, insurance companies know it, and if you have rack in your facility, you probably know it too. You have probably seen pallets break. You’ve seen drivers make mistakes when loading & unloading. We’ve seen things fall. If you’ve been in the business any length of time, you may have walked into your warehouse in the morning to find a case of something from the fourth level split open on the floor.

Tags: warehouse safety, storage, industrial accident prevention, Material Handling, Pallet Rack

Posted in Pallet & Warehouse Racks|

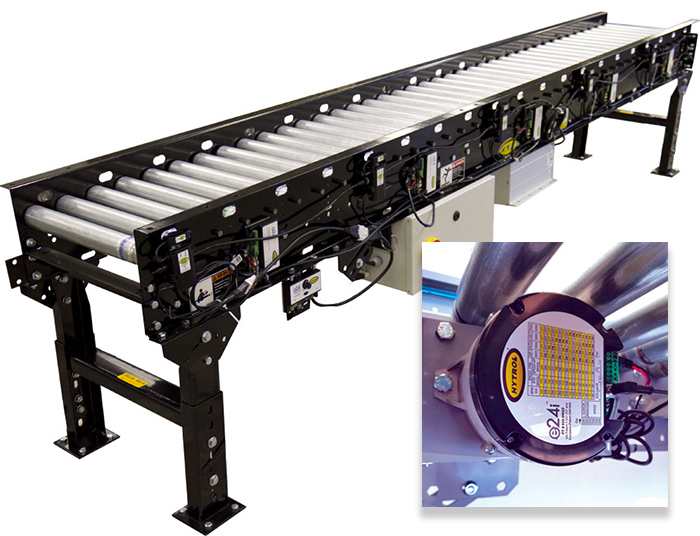

Seven Ways E24 Rollers Improve on Conventional Motorized Roller Conveyors

When Hytrol introduced its E24 powered roller conveyor system there was a splash – and rightly so.

E24 is a brushless, gearless, low RPM, high torque motor that drives conveyor rollers reliably and efficiently. The external motor provides exceptional flexibility, superb heat dissipation, and a robustness that cannot be achieved with motors embedded in conveyor rollers. But what really makes E24 superior to the conventional motorized roller conveyor?

Tags: Conveyor, Material Handling, power rollers, Hytrol, Conveying, roller conveying systems

Posted in Conveyor Optimization|

What Type of Industrial Shelving?

While there are dozens and dozens of shelving manufacturers and even more variations of trade names for them, there are really just three basic kinds of industrial shelving manufactured and broadly used — Rivet-Type, Steel Clip, and Wire. Of course, there are more variations of these shelving types than you can imagine, but most shelving boils down to these kinds.

Read the rest of this entry »

Tags: warehousing, Material Handling, industrial storage, shelving, shelves, facility maintenance, interior design

Posted in Storage, Organization & Workstations|

Basics: Rivet Shelving and Heavy-Capacity Applications

It’s safe to say that there is shelving of some kind in almost every warehousing or other industrial operation, offices, and most commercial facilities. Even a sophisticated distribution center outfitted with AS/RS usually has fallback storage in the form of rack or shelving. For those applications that require a lot of heavy-duty shelving, though, issues of capacity come to the forefront.

Tags: records storage, parts bins, archival, warehousing, warehouse safety, Industrial Shelving, storage

Posted in Storage, Organization & Workstations|

Am I Wasting Time: is Cross-Docking a Viable Consideration for my Company?

This article is the second in a series of articles on cross docking

In concept and on paper cross docking looks great, but, what about actual implementation? What kind of return do we get on this investment? The short answer is the implementation can be challenging. However, with planning, a committed team of upstream and downstream participants, and pilot programs, it can pay significant benefits.

Cross docking does not have to be complicated. Some, even today, execute cross-docking using human-readable paper documentation as the driver. As mentioned in the original brief, cross docking can cover a wide range of distribution activities. In one door and directly out the other is one approach. Many cross dockers also add value in the brief (hopefully) interval between receiving and shipping. Others send product to a temporary buffer in the interval, in many of these cases an automated system (mini-load, AS/RS, etc.) serves as the buffer.

Tags: Supply Chain, cross dock, Cross Docking, advance shipping notices, dock layout

Posted in Docks & Shipping|