Incentive programs are surprisingly common for industrial operations, and they can produce significant savings, quality increases and improved employee satisfaction – if the program is built correctly. In manufacturing, assemblers are often incentivized for quality and speed. In warehousing, it can be reduced product damage, pick rates, error rates or any number of other categories. When companies build out these programs, there are opportunities to create great value. How are companies going about this?

Read the rest of this entry »

Tags: personnel, labor, ROI, industrial, Incentives, warehouse workers, bonus programs

Posted in Manufacturing|

Things get a little messy sometimes in most industrial facilities. Or a lot messy.

Areas where sprays and aerosols are used aren’t friendly to the rest of the operation, but they also need to exist in the same facility. Perhaps thermal zones are needed where there was once plenty of space. Welding stations may be in areas more highly populated with other workers. Amongst all these considerations is also the fluidity of your operations as the company grows and changes. Are permanent solutions (walls) the right answer?

Read the rest of this entry »

Tags: privacy screen, vinyl walls, curtain walls, welding screens, acoustic panels, thermal walls

Posted in Safety & Ergonomics|

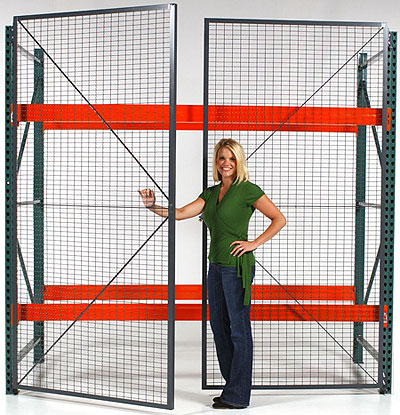

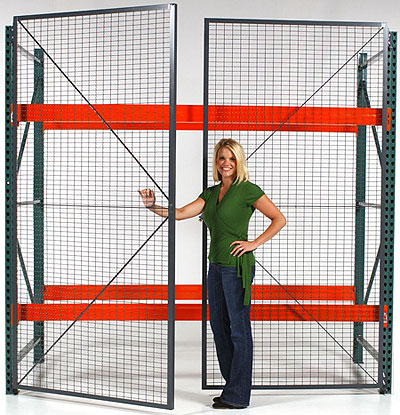

Warehouse security is sometimes slighted – other than perhaps exterior door locks and perhaps alarms. Security professionals will tell you that security is substantially about access to desirable items. How can you limit it? Let’s take a look at security equipment that can reduce temptation and help to keep vandals away from expensive exterior equipment.

Read the rest of this entry »

Tags: woven, welded, mesh, expanded steel, security cabinet, truck, security products, wire cage, wire partition

Posted in Security|

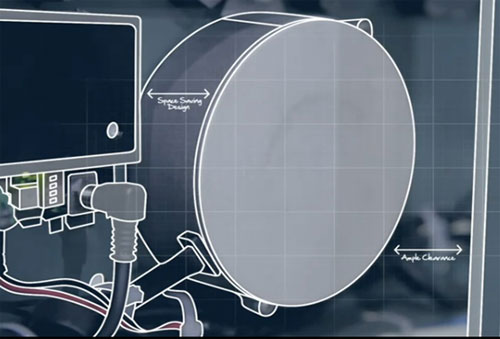

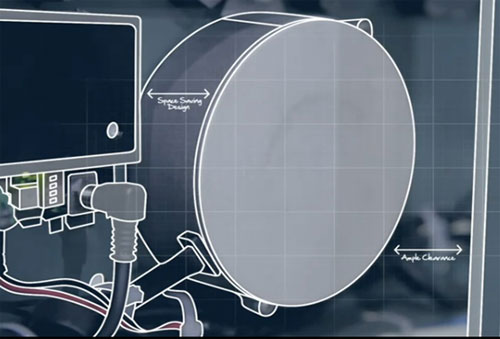

Since Hytrol rolled out the e24™ 24-volt motor conveyor in 2008 at Pack Expo at the Cisco-Eagle booth, we have implemented many projects with the new technology. In fact, it has become 18% of power roller conveyor sales since then. Many manufacturers have copied the concept as well. Its advantages and cost savings are well documented, but this comparison takes it a step farther for several existing types of conveyors.

Posted in Conveyor Optimization|

Everyday functions of most warehouses and industrial operations fall within the realm of manual material handling–constant lifting, bending, stretching, reaching, pushing and otherwise manipulating materials by physical force. People are moving cartons, picking orders, reaching for packing materials and performing other tasks. Manual material handling contributes to musculoskeletal disorders, to the tune of more than 500,000 reported annual reported cases of strains and stress in shoulders, backs, arms and legs.

While you can never eliminate it, you can reduce the worst aspects of it. Let’s dive into some ways.

Read the rest of this entry »

Tags: industrial safety, ergonomics, lifting, manual material handling, musculoskeletal

Posted in Safety & Ergonomics|

Like the Paul Simon song goes, there are 50 ways to pick an order—except in reality there are far more.

With such a variety of methods, processes, technologies and equipment options out there, it can be challenging to determine the best ways to improve order processing efficiency and productivity. In this article, LIDD’s Charles Fallon discusses 10 ways for distribution center managers to boost their order picking crew’s performance.

Read the rest of this entry »

Tags: Automation, productivity, labor

Posted in Order Picking & Fulfillment|

Carton flow expedites pick operations by making stock accessible in an easily replenished first-in/first-out pattern. Gravity flow racks can reduce labor costs up to 75% in pick operations compared to static storage picking by delivering cartons and split case goods to the pick aisle rather pickers pulling from the static pallet rack storage. It is a commonly used storage/picking method in many operations, but there are many options and types of flow storage available. Which fits your need best?

Read the rest of this entry »

Tags: mobile tilt shelving, rail flow, gravity carton flow, roller track, skate wheel bed flow, pick shelving

Posted in Order Picking & Fulfillment|

Most operations maintain at least some numbers on the most critical aspects of the business. For order picking operations, you might track number of orders picked per day, hours per pick, cost-per-pick, on-time rates — and error rates. The question is this: how accurate are those numbers? For instance, if your system reports 50 order picking errors a week, does that represent half your errors? All of them? Most of them? It’s can be difficult to understand.

Read the rest of this entry »

Posted in Order Picking & Fulfillment|

Steel guard rail is one of the best–and most economical–accident prevention tools in a facility’s safety arsenal. It helps keep workers safe from forklift traffic, protects valuable equipment from potential damage, and even guards ends of pallet rack rows. But there may be times when you need forklift or cart access to protected areas (or simply don’t want to step over or around railing). How do you handle those situations? How often are you having to remove your guard rail and then reassemble? There’s a better way available — lift-out rail systems.

Read the rest of this entry »

Tags: lift-out/drop-in, drop-in, access point, lift-out, guard rail systems, Lift-out guard rail

Posted in Safety & Ergonomics|

When your conveyor motor stops working, do you know what you need to know to replace it quickly? How do you even know what the original motor was rated?

Read the rest of this entry »

Tags: rpm, frame size, voltage, motor, single phase, 3-phase, Baldor, replacement motor, Conveyor, enclosure, electric motor, horsepower

Posted in Conveyor Optimization|

Read our customer reviews