Push back rack systems are excellent high density storage solutions — perhaps the most economical way to squeeze space out of a crowded warehouse. All loads are stored and retrieved from the same aisle. This reduces the number of aisles needed in a facility, freeing up more space for storage. Aisles can take a great deal of space up in a typical warehouse, so by implementing a pushback pallet rack system, you essentially swap selectivity for space. Push back rack systems provide a Last-In-First-Out (LIFO) inventory rotation, so you have to be certain your load fits. If it does, congratulations — you’ve just saved a lot of space.

But there are issues that can arise when pushback rack is inappropriately specified or utilized.

Read the rest of this entry »

Posted in Pallet & Warehouse Racks|

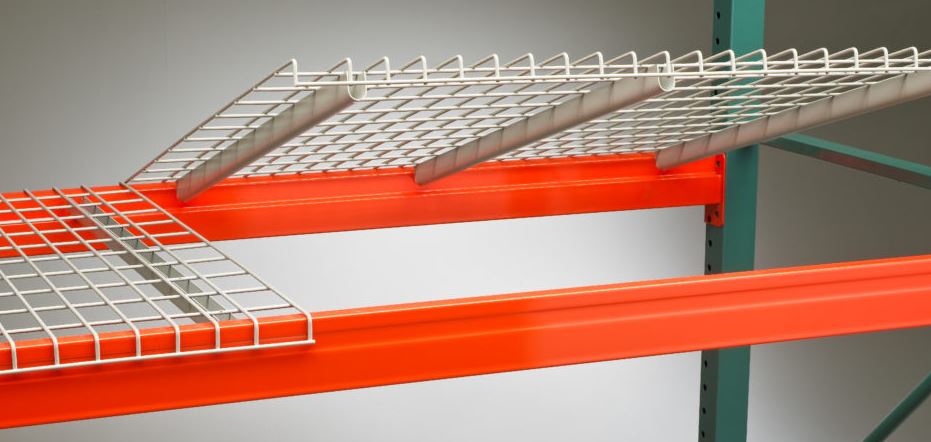

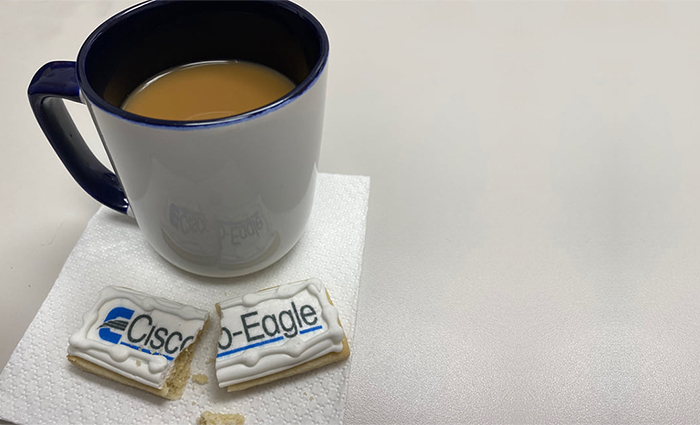

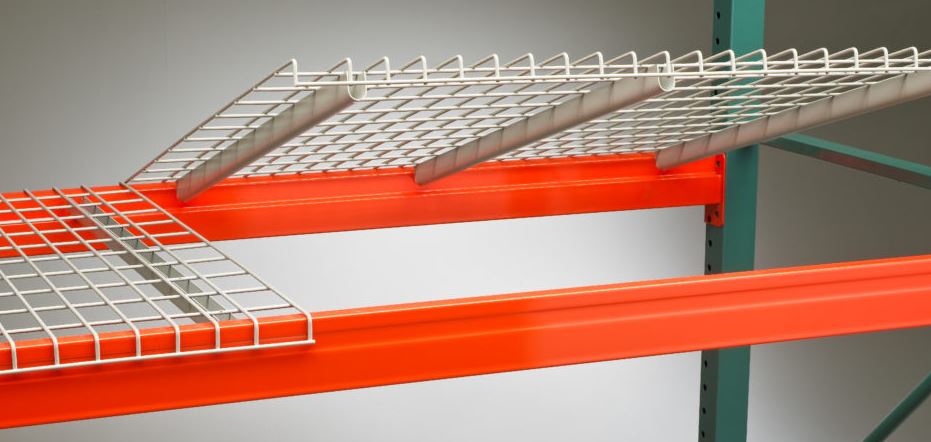

The Material Handling Industry of America recently announced that the RMI (Rack Manufacturers Institute) has certified several manufacturers of wire rack decking “R-Mark” compliant, meaning that these companies have conformed to the Institute’s testing and utilization standards.

Read the rest of this entry »

Tags: Pallet Rack, wire decking, industrial storage, warehousing, Material Handling

Posted in Pallet & Warehouse Racks|

When you are running an operation with lots of racking, it isn’t uncommon to have to replace an occasional upright or beam, or to add new bays onto an existing row. Sometimes you cannot avoid it, as the rack was purchased years ago, by someone else, or from a source you can’t even locate. It might be that you bought used rack and need to fill some gaps in, or it may be perfectly good, 10-year old rack that just needs some damaged components replaced.

This is done all the time, and although it isn’t an optimum situation for rack stability and safety, you can minimize the issues by following the following guidelines:

Read the rest of this entry »

Tags: warehousing, Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention, beams, uprights

Posted in Pallet & Warehouse Racks|

Safety in warehouses tends to be greatly about the interactions between forklifts, pallet racks, people and stored products. This list of rack safety tips is part of our ongoing efforts to help warehouses operate safely and efficiently.

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

Craig Chamberlain has an article over at the MHEDA Edge website that you need to read if you use pallet rack wire decking.

Here’s the money quote:

“Decking can, and often does, directly bear the total weight of the application’s load and transfers that load to the beams of the pallet rack. Regardless of the weight-bearing capacity of the rack’s beams, an improperly overrated deck can and will jeopardize the load-bearing capacity of the entire system and result in a failure.”

Read the rest of this entry »

Tags: OSHA, warehouse safety, facilities maintenance, wire rack decking, Material Handling, Pallet Rack

Posted in Pallet & Warehouse Racks|

Pallet racks take a beating over time. They get loaded with exceptionally heavy pallets, by exceptionally powerful lift trucks over and over throughout the course of years. Chances are that if you have pallet rack in your warehouse, it’ll get hit at some point. When it does, inspecting (and generally replacing) it is your best course of action. But what about avoiding that hit, or its dangerous aftermaths in the first place?

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, OSHA, warehouse safety, facilities maintenance

Posted in Pallet & Warehouse Racks|

Walk into any order fulfillment operation, and you will see gravity flow rack.

The reason is obvious–it’s one of the best ways to pick orders utilizing first-in, first-out principles. It used to be that there was one kind of the stuff, the plastic-wheel tracks, but these days the choices are more diverse than ever. For the most part, these flow rack types act the same; they decline toward the picker and boxes or totes or even larger components flow toward him. They’re restocked from the rear and picked from the front onto a takeaway conveyor line, a cart, workstation, or another step in the process.

Read the rest of this entry »

Tags: warehousing, Material Handling, Hytrol, order fulfillment, Supply Chain, carton flow, gravity flow rack, distribution center, Unex, Keneco, Conveyor, picking systems

Posted in Order Picking & Fulfillment|

Unguarded rack is dangerous if there are people working in the aisles below. Safety managers know this, insurance companies know it, and if you have rack in your facility, you probably know it too. You have probably seen pallets break. You’ve seen drivers make mistakes when loading & unloading. We’ve seen things fall. If you’ve been in the business any length of time, you may have walked into your warehouse in the morning to find a case of something from the fourth level split open on the floor.

Read the rest of this entry »

Tags: Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

Above: Belt conveyors hang from the ceiling of a busy e-commerce distribution center, feeding shipping operations from a pick module while leaving the space below for traffic and shipping activities.

Conveyor systems transform picking, transport, assembly, and more, but occupy space in fixed positions. Tight layouts, low ceilings, facility structures and equipment compromise and compete for that square footage. Don’t worry, though—there are creative ways to work circumvent those limitations–and in some cases make them strengths.

Read the rest of this entry »

Posted in Conveyor Optimization|

write an introduction for this article

Tags: Automation, shipping, labor

Posted in Industry Insights|

Read our customer reviews