Building a more ergonomic material handling operation almost always equates to building a more efficient one. People who don’t need to bend, strain or lift as often are usually more effective, faster and less prone to injury. If it takes energy or time to turn, lift or maneuver a load, it’s this simple: you’re losing productivity. Many companies use scissor lift tables to help them lift heavy and bulky loads and can make the process even better by understanding what happens when that load reaches its desired height.

Scissor Lift Platform Options for Improved Productivity & Ergonomics

Tags: ergonomics, facility safety, Conveyor

Posted in Lifting & Lift Systems|

Vertical Conveyors Loading and Unloading Integration

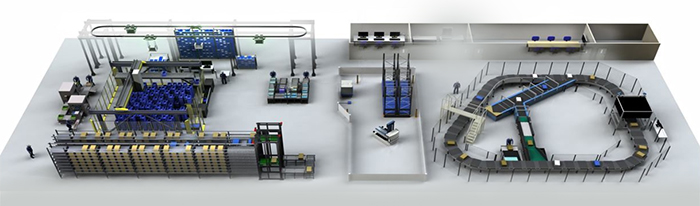

There are many ways to transport products vertically in a warehouse or manufacturing operation, each with its distinctive advantages and limitations. These methods can range from extremely basic – a forklift and a pallet – to fully-integrated, automated systems. Vertical conveyors are one of the most common methods for certain loads and situations. What are some of the integration factors for these conveyors, and how can you handle them?

Tags: work platforms, conveyors, mezzanine

Posted in Lifting & Lift Systems|

Forklift Proximity Detection – Do More Zones Matter?

You’ve seen them pass so close in your facility it stopped you cold. Keeping forklifts and pedestrians from collision (or even close encounters) is a critical element of safety within any facility that uses both. Creating a safe culture that improves these interactions is the goal of any team, and there are many solutions available.

Outfitting your workers and trucks with proximity warning systems is a solution designed to improve these interactions. These systems are a crucial component of occupational safety strategies, significantly diminishing the likelihood of accidents and incidents between pedestrians and vehicles, and effectively fostering a culture of heightened safety awareness among employees

As proximity warning systems evolve, they now boast new features. Notably, some are exploring dual detection zones, with the thought of extra protection. This innovation prompts us to question: does an extra detection zone boost accident prevention effectiveness?

Posted in Forklift - Pedestrian Safety|

Stress and The Warehouse Worker: What are the Issues?

This month, we delve into the stresses faced by warehouse workers, and how that may play into the sector’s competitiveness for labor as the available pool continues to contract. Also: detailed data on manufacturing output, ROI for industrial capital spending, and a bit more.

Tags: Automation, Manufacturing, labor

Posted in Industry Insights|

How to Convey Heavy, Fragile Cartons

Beverage handling systems have always been challenging. Cartons of expensive wine and liquor are heavy – and dense. And prone to damage. Sometimes these loads can be perishable and need to move fast through a system from picking to packing. The need to serve both retail and ecommerce customers from the same facility also complicates these design challenges.

Tags: warehousing, product damage, ergonomics, order fulfilment

Posted in Conveyor Optimization|

10 Easy Tips to Increase Warehouse Safety

Insufficient safety measures in warehouse and distribution centers can have severe repercussions, including injuries, operational downtime, product losses, property damages, and potential legal actions. Of particular concern are accidents involving collisions between forklifts or other vehicles and employees or visitors.

Within busy operations, a forklift or other vehicle may eventually run into existing rack. While the rack may not require immediate replacement, storage capacity and product throughput may be compromised for some time. If overloaded, or loaded incorrectly, a rack can also collapse, spilling the inventory to the ground. Employees and visitors must also be protected from vehicle traffic.

Posted in Pallet & Warehouse Racks|

Increase Vehicle Access With The Right Loading Dock Lift

I suspect you’ve heard somewhere that your dock is the “lifeblood” of your facility. Certainly, there’s no denying this reality, given that so much consistently flows in and out of this highly charged area. The name of the game is to create the most efficient movements within your dock while also keeping a watchful eye on the safety and security of those within it.

To move more and reap more from that, you want to allow for any type of delivery vehicle to enter and exit. There’s certainly a wide variety, and enhancing your existing physical dock location and limitations is key.

Posted in Docks & Shipping|

Warehouse Ergonomics and Productivity: an Inseparable Relationship

Improving the ergonomics of any warehouse operation may be the single easiest way to improve productivity – and that’s aside from the obvious safety and labor force protection aspects. Consider all the ways people move and work every day, every week, every year. Those repetitive motions take a toll both on the people doing the work and overall productivity. Ergonomics and productivity are not only related: they’re essential to each other.

Posted in Safety & Ergonomics|

Manufacturing Expansion: Who, What, Where and How?

As we enter 2024, it’s no secret that manufacturing is growing at a nearly unprecedented rate. This cycle has been on the rise for years, and is now accelerating. Beneath the surface, some regions and sectors are growing faster than others. What are the trends we can anticipate in 2024 and beyond?

Tags: Manufacturing

Posted in Industry Insights|

Warehouse Automation: The Cost of Doing Nothing

People who operate industrial facilities have a difficult task. While the world changes around them, they’re dealing with a static operation that can be difficult to change or revitalize. Sunk costs, funding and organizational inertia can paralyze you at the worst moments. But the reality is that from our supply chains to labor to our customer demand profile, things are always in flux.

Tags: AS/RS, conveyors, labor management, Robotics

Posted in Automation, Labor & Efficiency|