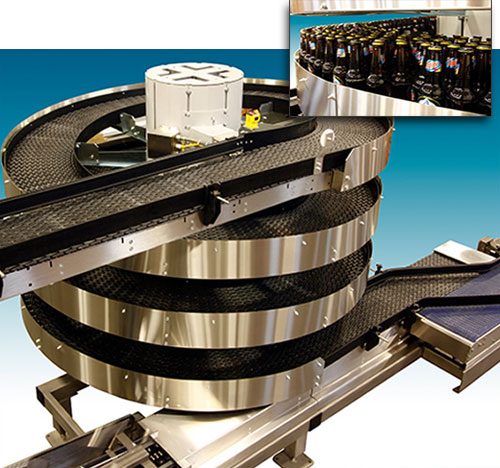

In any warehouse or distribution facility, there are two critical—and usually very limited—commodities: time and space.

Warehouses and DC’s are limited by these two constraints – you basically have your square footage, your people, and 24 hours in a day—or less, if you aren’t running three shifts. These constraints drive us to refine processes and optimize performance. Let’s discuss a type of equipment that can save time and slash the need for space: spiral conveyors.