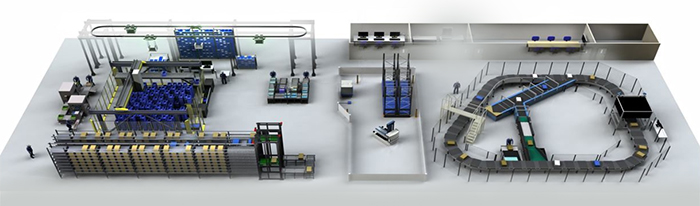

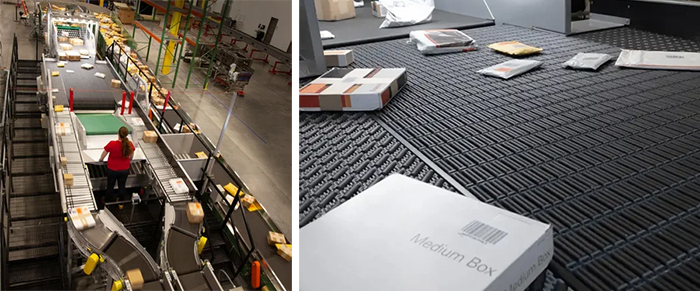

I suspect you’ve heard somewhere that your dock is the “lifeblood” of your facility. Certainly, there’s no denying this reality, given that so much consistently flows in and out of this highly charged area. The name of the game is to create the most efficient movements within your dock while also keeping a watchful eye on the safety and security of those within it.

To move more and reap more from that, you want to allow for any type of delivery vehicle to enter and exit. There’s certainly a wide variety, and enhancing your existing physical dock location and limitations is key.