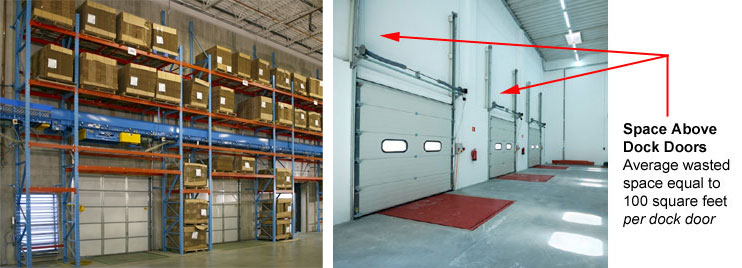

Walk any warehouse, manufacturing facility, or commercial storage operation and you’ll almost always find two things: forklifts and dock doors.

If that building has been in place for any length of time, you’ll also find dinged, dented, ruined or replaced dock door guides, pallet rack frames, building columns, etc. While many operations take steps to use guard rails or bollards to shield their critical machinery, dock doors can be left out.