The Material Handling Industry of America has posted a video that may be helpful if you are starting the process of “greening” your supply chain.

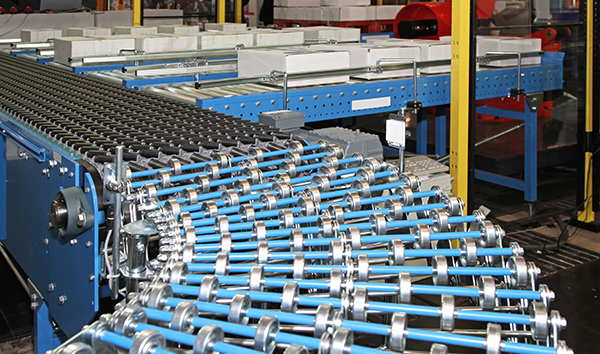

Baby steps are important, especially at the plant level. For instance, in a recent Cisco-Eagle white paper (PDF), we point out the value of energy efficient conveyor motors. A thousand feet of conveyor outfitted with energy efficient motors could cut enough energy costs over five years to pay for 90% of the cost of the equipment. Also, besides its money savings and “green” profile, you are also saving on heat, which means the equipment may require less maintenance, and endure less wear and tear. It’s a win-win.