With the growing popularity of automating the palletizing function, we arranged an interview with vonGAL, a leading manufacturer who has the largest installed base of palletizers in the country. Bobby Edmond is vonGAL’s Director of Applications, and has been in the business for 25 years. He has seen applications in a wide range of industries, and in companies large and small. I asked him if he would take time to share his thoughts, and answer a few questions of interest to those that might be considering palletizing for the first time.

Palletizer Perspectives: Is Palletizing Suitable for My Operation?

Tags: Factory Automation, warehousing, Material Handling, shipping, order fulfillment, Palletizers, palletizing

Posted in Automation, Labor & Efficiency|

Options for Mobile Weighing Technologies in the Warehouse

In dynamic distribution environments, accurate, fast weighing, counting, and dimensioning systems are more important than ever. This is particularly true in 3PLs and other operations where needs often change. Getting it right, and getting it quickly has become increasingly more important. One way is to utilize the newer mobile weighing systems on the market today.

Tags: Material Handling, scales, industrial weighing systems, inventory accuracy, warehousing

Posted in Warehousing & Distribution|

How to Minimize Forklift Impacts on Pallet Racks

Pallet racks take a beating over time. They get loaded with exceptionally heavy pallets, by exceptionally powerful lift trucks over and over throughout the course of years. Chances are that if you have pallet rack in your warehouse, it’ll get hit at some point. When it does, inspecting (and generally replacing) it is your best course of action. But what about avoiding that hit, or its dangerous aftermaths in the first place?

Tags: Material Handling, Pallet Rack, OSHA, warehouse safety, facilities maintenance

Posted in Pallet & Warehouse Racks|

Palletizers: Ergonomics and Justification

As interest continues to grow in automated palletizing, let’s take a brief look at a few of the issues surrounding these applications.

Over the next couple of months, I’ll be providing a handful of blog postings relative to palletizers. We will begin with what is driving the growth in the use of these products, then a look at basic systems, cost estimates, what you can expect from a properly applied palletizer system, and then share specifics from a couple of actual implementations in distribution centers. If you are experienced in palletizer systems, you will likely be familiar with much of what is covered here. If you are new to palletizing, or considering your first system, hopefully, this information will help you understand what the issues are and how you can navigate them.

Tags: order fulfillment, Palletizers, palletizing, ergonomics, Factory Automation, warehousing, Material Handling, shipping

Posted in Automation, Labor & Efficiency|

Comparing Gravity Flow Rack Types

Walk into any order fulfillment operation, and you will see gravity flow rack.

The reason is obvious–it’s one of the best ways to pick orders utilizing first-in, first-out principles. It used to be that there was one kind of the stuff, the plastic-wheel tracks, but these days the choices are more diverse than ever. For the most part, these flow rack types act the same; they decline toward the picker and boxes or totes or even larger components flow toward him. They’re restocked from the rear and picked from the front onto a takeaway conveyor line, a cart, workstation, or another step in the process.

Tags: Hytrol, order fulfillment, Supply Chain, carton flow, gravity flow rack, distribution center, Unex, Keneco, Conveyor, picking systems, warehousing, Material Handling

Posted in Order Picking & Fulfillment|

Modular Storage Considerations

Something we often recommend to save space for our clients is modular drawer storage — for certain operations, in particular those with components, assorted small parts, hardware, or even tool storage, we’re talking about recouping 50% -70% of floor space. Once people have ’em, they love ’em.

Something we often recommend to save space for our clients is modular drawer storage — for certain operations, in particular those with components, assorted small parts, hardware, or even tool storage, we’re talking about recouping 50% -70% of floor space. Once people have ’em, they love ’em.

But there is more than one way to skin that cat. You can configure different kinds of cabinets to do different jobs. There are hundreds of possible combinations of drawer styles and sizes. Another wrinkle is what happens when you can merge the drawers with steel shelving. It can be new, it can be some you are already using. It begs the question: when is it better to have a cabinet, and when is it better to use shelving and compartmentalized drawer inserts?

Tags: Material Handling, security, space savings, tool storage, Industrial Shelving, small parts, modular storage, warehousing

Posted in Storage, Organization & Workstations|

Tips to Fight Summer Heat in the Warehouse

There are many issues of productivity and safety that are stressed as the heat rises. As temperatures start to rise, it gets particularly hot in industrial facilities, warehouses, shops, and distribution centers where air conditioning isn’t always present, extremely costly, or very effective. Experts say that employee productivity increases when ambient temperatures are comfortable and plummets when they aren’t. Error rates climb and safety is compromised as workers fight through hot, sweaty conditions. Here are some ways you can go about combating the rigors of summer.

Tags: warehousing, Material Handling, industrial safety, heat stress, heat exhaustion, industrial fans, climate control, fans, Conveyor

Posted in Safety & Ergonomics|

Comparing Pallet Rack Guards: Flexible Netting vs. Wire Mesh Panels

Unguarded rack is dangerous if there are people working in the aisles below. Safety managers know this, insurance companies know it, and if you have rack in your facility, you probably know it too. You have probably seen pallets break. You’ve seen drivers make mistakes when loading & unloading. We’ve seen things fall. If you’ve been in the business any length of time, you may have walked into your warehouse in the morning to find a case of something from the fourth level split open on the floor.

Tags: Material Handling, Pallet Rack, warehouse safety, storage, industrial accident prevention

Posted in Pallet & Warehouse Racks|

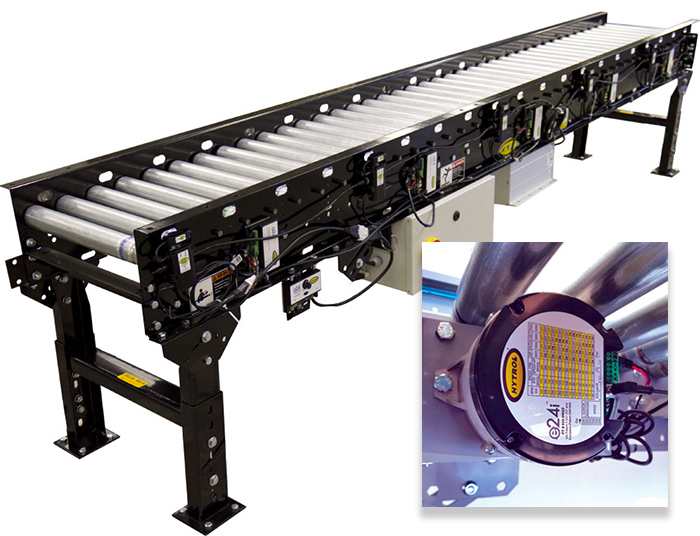

Seven Ways E24 Rollers Improve on Conventional Motorized Roller Conveyors

When Hytrol introduced its E24 powered roller conveyor system there was a splash – and rightly so.

E24 is a brushless, gearless, low RPM, high torque motor that drives conveyor rollers reliably and efficiently. The external motor provides exceptional flexibility, superb heat dissipation, and a robustness that cannot be achieved with motors embedded in conveyor rollers. But what really makes E24 superior to the conventional motorized roller conveyor?

Tags: power rollers, Hytrol, Conveying, roller conveying systems, Conveyor, Material Handling

Posted in Conveyor Optimization|

What Type of Industrial Shelving Would Work Best for You?

While there are dozens and dozens of shelving manufacturers and even more variations of trade names for them, there are really just three basic kinds of industrial shelving manufactured and broadly used — Rivet-Type, Steel Clip, and Wire. Of course, there are more variations of these shelving types than you can imagine, but most shelving boils down to these kinds. You can also consider bulk rack as “shelving”, but we have found that heavy duty rivet shelving often fulfills the roles it has typically filled.

Read the rest of this entry »

Tags: warehousing, Material Handling, industrial storage, shelving, shelves, facility maintenance, interior design

Posted in Storage, Organization & Workstations|